Page 4

DETAIL A

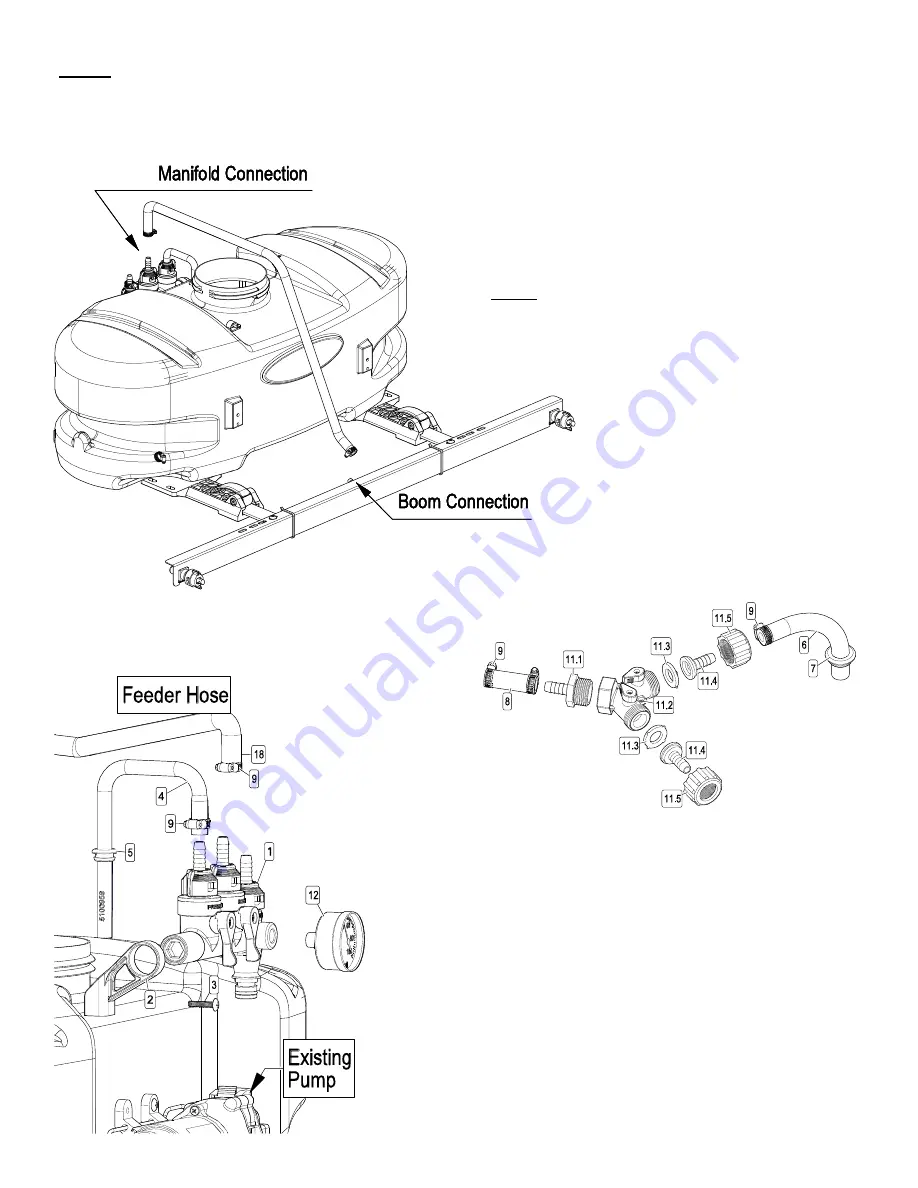

Step 4

After your nozzle harness is attached to the boom, lo-

cate the 43” hose and the (2) hose clamps from the

parts bag.

Place the hose clamps over each end of the hose

loosely. Slip the ends of the hose over the hose barbs

on both the manifold and the poly tee fitting on the

nozzle harness. Use a twisting motion, if necessary, to

get the hose fully onto each barb. Bring the hose

clamps to the connection point and tighten securely.

NOTE:

Make sure this boom feeder hose does not end up on

the ‘outside’ of your spray wand hose, otherwise un-

wrapping the spray wand hose from around the tank

may be difficult.

An additional set of plumbing fittings may be included with your

boom kit. These may or may not be used.

DETAIL A: shows the configuration of these fittings as they will

attach to your sprayer when hooking up to a 1.0 gpm pump.

For the ‘old style’ tank, where the pump mounts on top, a hole

must be drilled through the top of the tank for the bypass return

hose. After threading the fittings together, locate the place on

your tank for the place on your tank for the hole, so that the

hose can be inserted without causing kinks.

If your sprayer has the manifold assembly off the outlet side of

your pump (DETAIL B), you probably will not need to utilize

these fittings.

Assembly Procedure (ATVBK-200-QR)

DETAIL B