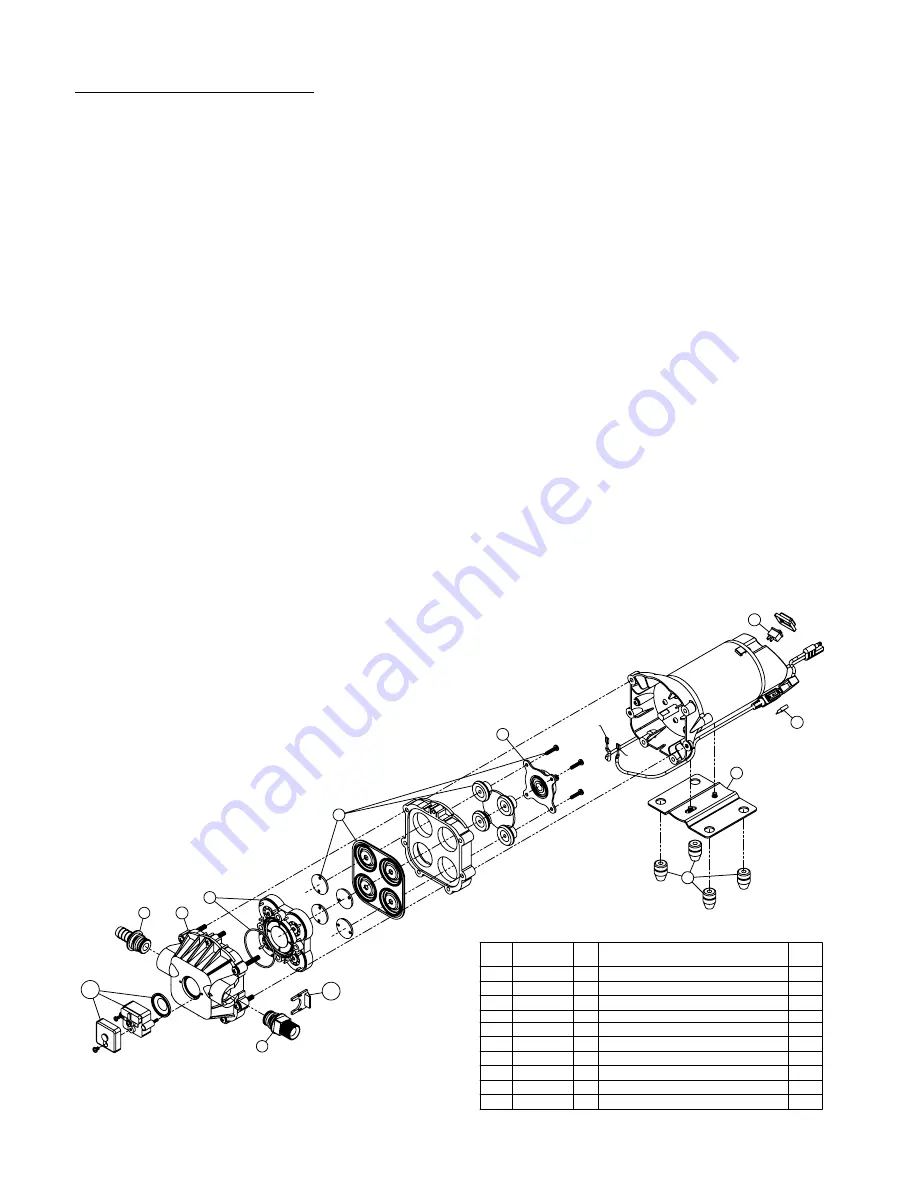

#5275704 Pump

(12 Volt, 11 Amp, 3.8 gpm, 45 psi)

4

3

1

2

7

8

5

5.2

5.1

6

"A"

"B"

*

*

Page 5

- Make sure the bypass line valve is closed, to allow the

pressure to build up in your system.

- Unscrew the head portion of your pump and remove the

check valve assembly from inside. You need to make

sure the O-Ring comes out with this piece as well. (See

the exploded view to help identify these components)

These pieces can be cleaned which, in most cases, will

help restore some, if not most, of your prime. Soak this

check valve in a solution of hot, soapy water. "Dawn"

brand dishsoap works well for this. A little bit of

'scrubbing' with perhaps an old toothbrush may be

required to actually break up any build-up that may be on

the check valve. Rinse off the pieces and replace them

back into your pump. Reassemble the pump. Hook it back

up and test.

Troubleshooting a 3.8 g.p.m. Pump:

Pump will NOT run:

- Check inline fuse on the wires on the pump. If blown,

replace with new fuse. (15 Amp mini-blade fuse #5157206)

- Make sure BOTH on/off switches are in the 'on' position (-).

- Make sure you 12 volt source (battery) is fully charged.

- Insure a tight connection at the battery clips.

If none of the above will work, try pulling wire terminal "A" off

of the spade terminal of the pressure switch, and cross it

over and touch terminal "B". (You will need to remove the

pressure switch cap before doing this) If your pump runs

when you do this, you know you will need to replace your

pressure switch.

Another thing you can try is to take apart the switch box on

the lead wire assembly (#5274443) with the (2) phillips head

screws, and 'hot-wire' it together. Take the (2) wires that are

screwed to the rocker switch, off of the switch and twist

them together. This will insure you are getting the full 12

volts to the pump. If your pump runs after doing this, you will

know that your lead wire assembly needs to be replaced.

Pump runs, but does not prime:

- Check line strainer (screen) at the inlet location, at the

tank. You will need to unscrew the knurled nut to access

this screen. (see exploded view later in this manual) The

ON/OFF valve should be closed while performing this, to

insure you do not lose any solution. Periodically take the

screen at this location out and clean it.

Fittings with an asterisk (*) by

them, come together in a bag,

part #7771831.

(1) 5168832 - 1/2" MNPT

(1) 5168833 - 1/2" Hose Barb

Item

No

Part

Number

Qty Description

List

Price

1

5029092

1 Base Plate (Quad Pump)

9.25

2

5075019

1 Pkg. (4) Grommets

2.99

3

5157206

1 15 Amp Mini Fuse

1.00

4

5157207

1 Rocker Switch

6.99

5

5168821

1 Upper Housing

39.95

5.1 20408-000 1 Pkg. (2) Clips (Port Fitting)

3.41

5.2

5157203

1 Pressure Switch Assembly

23.95

6

5168824

1 Check Valve Kit w/O-Ring & Ferrules

24.99

7

5168826

1 Diaphragm Kit w/Pistons & (4) Screws 19.96

8

5168828

1 Cam/Bearing Kit, w/Set Screw

12.95