Page 3

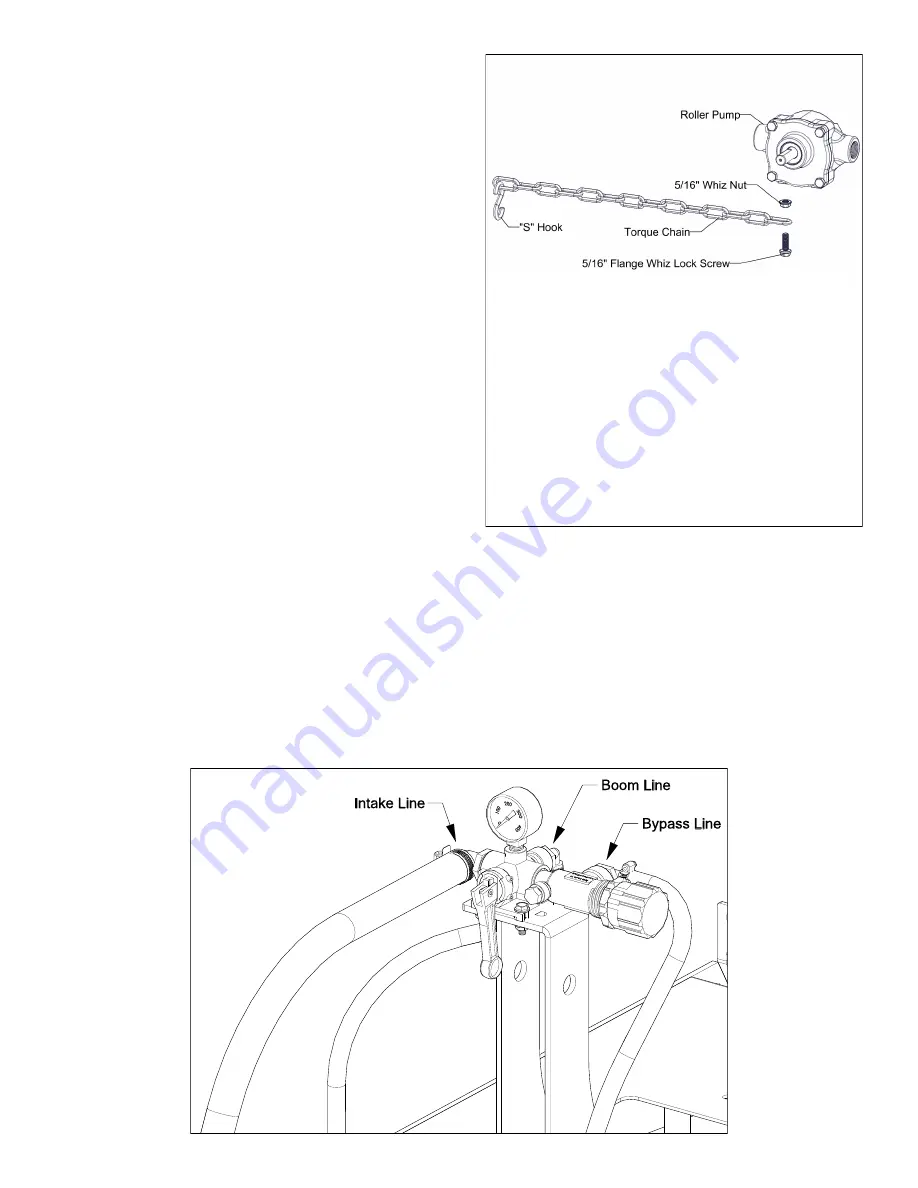

A torque chain, ‘S’ hook, nut and bolt are included in this assembly

to secure your pump during operation.

1.

Attach one end of the torque chain over the threaded stem of

the bolt

2.

Thread the whiz nut onto the bolt. Hand-tighten

3.

Thread the bolt, chain and nut ‘pre-assembly’ into the threaded

hole on the underside of the pump. Tighten sufficiently

4.

Affix the ‘S’ Hook to your frame (or hitch). Wrap the chain

around the frame or hitch and ‘S-Hook’ it in place. Make sure

this connection is very secure! Not having a good, tight con-

nection may result in the pump spinning on your PTO shaft

and damaging some components of your sprayer

*** Insure that this connection point will not allow the roller pump to

spin on the PTO shaft ***

Torque Chain Attachment to a Roller Pump

Maintenance During/After Spraying

Periodically check the strainer and clean the screen on your intake

line.

Proper care and maintenance will prolong the life of your sprayer.

After use, fill the sprayer half way with clean water. Start the pump

and allow the water to pump through the entire plumbing system and

nozzles. Drain and then refill half full, add the recommended amount

of a good quality tank cleaner, such as FIMCO Tank Neutralizer and

Cleaner. (If no tank cleaner is available, you may substitute dish

soap for this step). Turn pump on and circulate through system for

15 minutes and then spray out through boom and handgun nozzles.

Refill sprayer half way with clean water and repeat. Follow the chemi-

cal manufacturer’s disposal instructions of all wash or rinsing water.

If boom or handgun nozzles need cleaning, remove them from the

sprayer and soak in warm soapy water. Clean with a soft bristled

brush or toothpick if necessary. Never use a metal object. Even the

slightest damage can change the flow rate and spray distribution.

Water rinse and dry the tips before storing.

WARNING:

Some chemicals will damage the pump valves if al-

lowed to soak untreated for a length of time! ALWAYS flush the

pump as instructed after each use. DO NOT allow chemicals to sit in

the pump for extended times of idleness. Follow the chemical manu-

facturer’s instructions on disposal of all waste water from the sprayer.

Winter Storage

Drain all water out of your sprayer, paying special attention to the

pump, handgun and valve(s). These items are especially prone to

damage from chemicals and freezing weather.

The sprayer should be winterized before storage by pumping a solu-

tion of automotive antifreeze (containing a rust inhibitor) through the

entire plumbing system. This antifreeze solution should remain in the

plumbing system during the winter months. When spring time comes

and you are preparing your sprayer for the spray season, rinse the

entire plumbing system out, clearing the lines of the antifreeze

solution.

Proper care and maintenance will prolong the life of your

sprayer.