Page 6

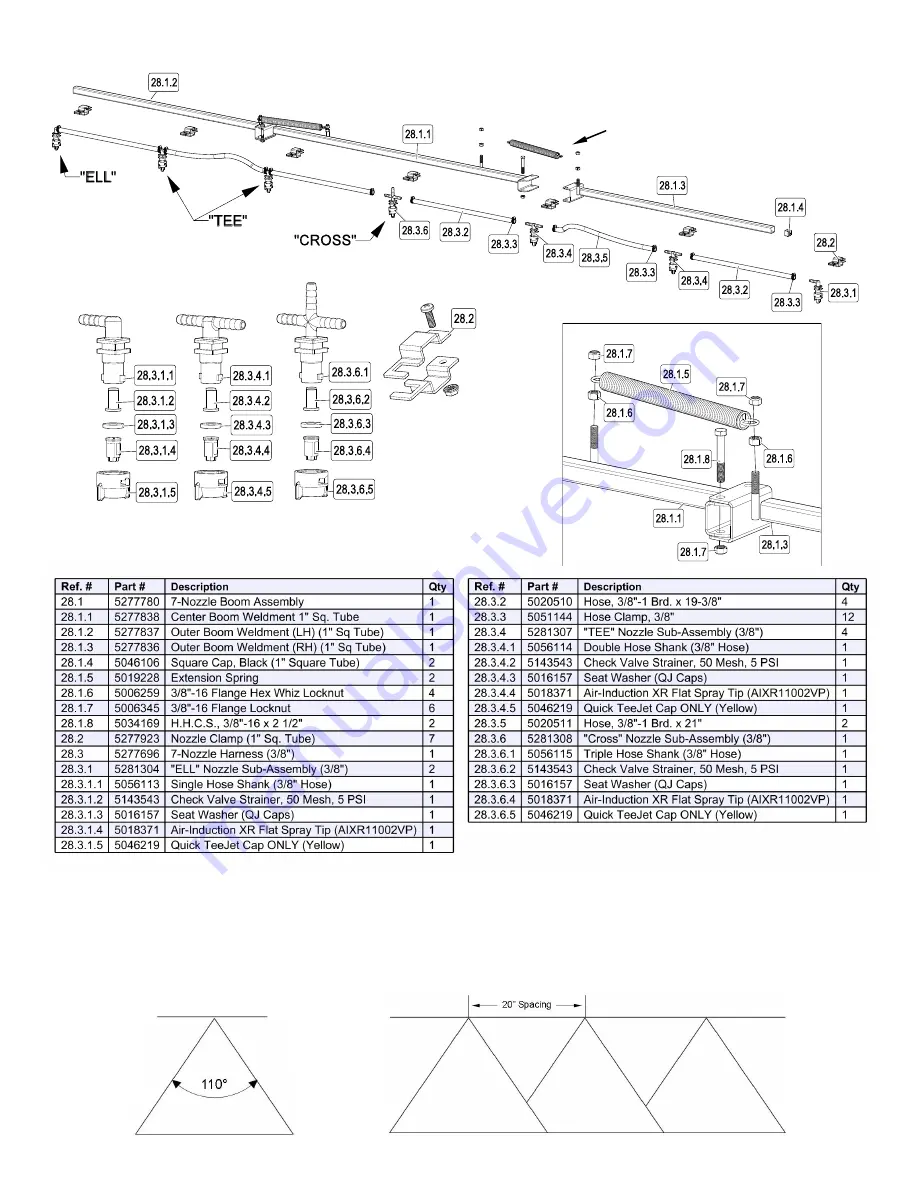

ELL TEE CROSS

Opposite side has typical hardware setup

Exploded View/Parts List: 7-Nozzle Boom Assembly

See Hinge Detail

Hinge

Detail

Based on the minimum overlap required to obtain uniform

distribution with 110° tips and 20” spacing.

Suggested Minimum Spray Height: 16”-18” above what is

being sprayed (to plant, not ground).

Optimum Spray Height: 20”

110° wide, tapered flat spray angle with air induction tech-

nology for better drift management

Made of 2-piece UHMWPE polymer construction which

provides excellent chemical resistance, including acids, as

well as exceptional wear life

Compact size to prevent tip damage

Excellent for systemic products and drift management

Clamp

Assembly

Bag of 7:

5277730