Page 2

IMPORTANT:

Remove tank lid and be sure the tank is

clean and free of any foreign material. Rinse tank out

of any tank residue before filling with water to test.

Testing the Sprayer

NOTE:

It is important that you test your sprayer for leakage and proper spray

patterns with plain water before chemical application is attempted.

This will also give you the opportunity to familiarize yourself with the

operation of the sprayer, without the possibility of losing any

expensive chemicals.

Operating the Sprayer

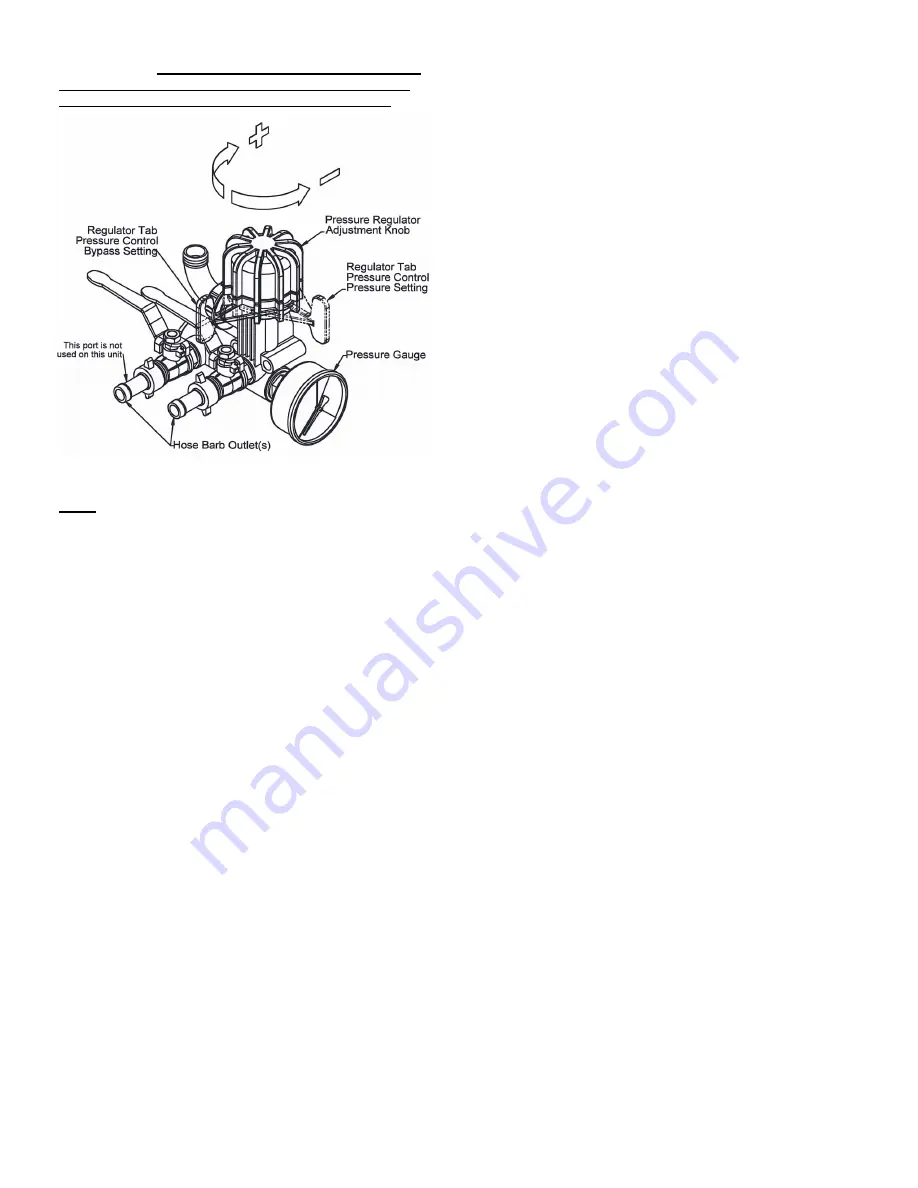

1.

Rotate the regulator tab clockwise as far as possible (0 PSI).

This aids in the starting of the engine.

2.

Make sure handgun is in the “off” position and start the engine.

3.

Open the handgun. Water should start to flow from the handgun

immediately. Leave the regulator tab in position (0 PSI) for

about 1 minute. Allow any air in the system to be worked out

before attempting to spray. Rotate the tab in the opposite

direction to increase the pressure.

4.

The pressure regulator (red knob on top) may now be rotated to

get the desired operating pressure. Operate the sprayer for a

short time with plain water and inspect the system again for any

leakage. The sprayer is ready to use.

5.

The valve in the agitator line may be used to limit flow and

pressure to the agitator.

**NOTICE**

1.

Be sure all guards covering exposed moving parts, such as

shafts, are in place at all times. DO NOT USE the sprayer

unless all guards are in place.

2.

Test the sprayer with plain water before adding chemicals to the

tank.

3.

DO NOT EXCEED recommended speed, pressure and

temperature for the sprayer and pump.

4.

High pressure spray can cause serious bodily injury. Handle

with care. Grasp gun firmly before starting to spray. During

spraying operation, hold gun firmly.

5.

DO NOT put hands or fingers in front of the gun or point the gun

at your body or anyone else.

6.

Before working on, servicing or making adjustments to

equipment, disengage power, shut off engine, make sure all

moving parts have stopped and all pressure in the system is

relieved.

7.

Perform periodic cleaning, maintenance and inspection of

fittings and hoses for operator safety. Replace any fittings or

hoses that are shown to have defects.

8.

DO NOT use sprayer for pumping water or other liquid for

human or animal consumption.

9.

If equipment is used in freezing or near freezing conditions,

protect pump and plumbing on sprayer from freezing. Drain

liquid from system and add RV antifreeze.

Maintenance During/After Spraying

Periodically close the suction line valve and check the line strainer

and clean the screen. Stop the engine and shut off the valve near

the strainer. Remove the bowl and screen portions of the strainer

and wash them free from all impurities. You may also drain the tank

by uncoupling the suction line near the strainer. Open the valve and

pour the contents into another container. Read the chemical label

for disposal instructions.

Proper care and maintenance will keep your pump wear at a

minimum and will keep it running smoothly and trouble-free for a

long time and prolong the life of your sprayer.

Change the engine oil per the engine manufacturer’s specifications.

Oil changes in the pump should be done after each 200 hours of

use or at least once a season. To fill the pump with oil, pour oil

slowly into the sight tube while slowly turning the pump shaft.

Turning the pump shaft purges all of the air from the crankcase. Use

SAE 30 motor oil.

Refer to the pump and motor owners manuals for their respective

replacement parts and service recommendations.

After use, fill the sprayer tank part way with water. Start the sprayer

and allow the water to pump through the entire plumbing system

and nozzles. Drain and then refill half full with plain water, add the

recommended amount of good quality tank cleaner such as FIMCO

Sprayer Tank Neutralizer and Cleaner. (If no tank cleaner is

available, you may substitute dish soap for this step, about 1-2 oz.

per gallon). Turn sprayer on and circulate through system for 15

minutes and then spray out through handgun nozzle (and boom

nozzles if applicable). Refill tank half way with clean water and

repeat. Follow the chemical manufacturer’s disposal instructions of

all wash or rinsing water.

For the boom (if applicable) remove the tips and screens from the

nozzle assemblies. Wash these items out thoroughly. Blow the

orifice clean and dry. If the orifice remains clogged, clean it with a

fine bristle (NOT WIRE) brush or with a toothpick. Do not damage

the orifice. Water rinse and dry the tips before storing.

WARNING:

Never pump corrosive or abrasive liquids as these will

cause rapid wear or deterioration of body, rotor, shaft and seals in

the pump. Never run pump dry. Some chemicals will damage the

pump valves if allowed to soak untreated for a length of time!

ALWAYS flush the pump as instructed after each use. DO NOT

allow chemicals to sit in the pump for extended times of idleness.

Failure to follow this warning will void the product warranty.

Follow the chemical manufacturer’s instructions on disposal of

all waste water from the sprayer.

Winter Storage

Prepare the sprayer for end-of-season storage by running RV

antifreeze through the system. This will keep internal parts

lubricated, protect against corrosion and keep the unit from freezing.

Note: RV antifreeze is non-toxic and biodegradable and generally

safer for the environment than automotive antifreeze.

Before storing your sprayer for winter or long term storage,

thoroughly clean and drain it as much as possible. Then pour

enough pink RV antifreeze into the tank so that when the pump is

turned on you can pump the antifreeze throughout the entire

plumbing system, including the bypass. Make sure to operate the

boom (if applicable) and handgun until you see pink fluid spraying

from the nozzles. Leave any remaining antifreeze in the tank.

Before your next usage, rinse the antifreeze from the sprayer with

clean water.

It is nearly impossible to drain all of the water from the sprayer and

any trapped water can freeze in cold weather and damage parts of

the sprayer. Pumping the antifreeze through the system will

displace the water and help prevent this damage.

Removing from storage: drain the antifreeze. Fill the tank with fresh

water and run through the system. Dispose of antifreeze and flush

water properly.

Removing the pump from the sprayer and storing it in a heated area

will also prevent costly damage to the pump. This should be done

AFTER the pump has been neutralized and flushed out with RV

antifreeze. Plug the inlet and outlet ports if storing inside.