12

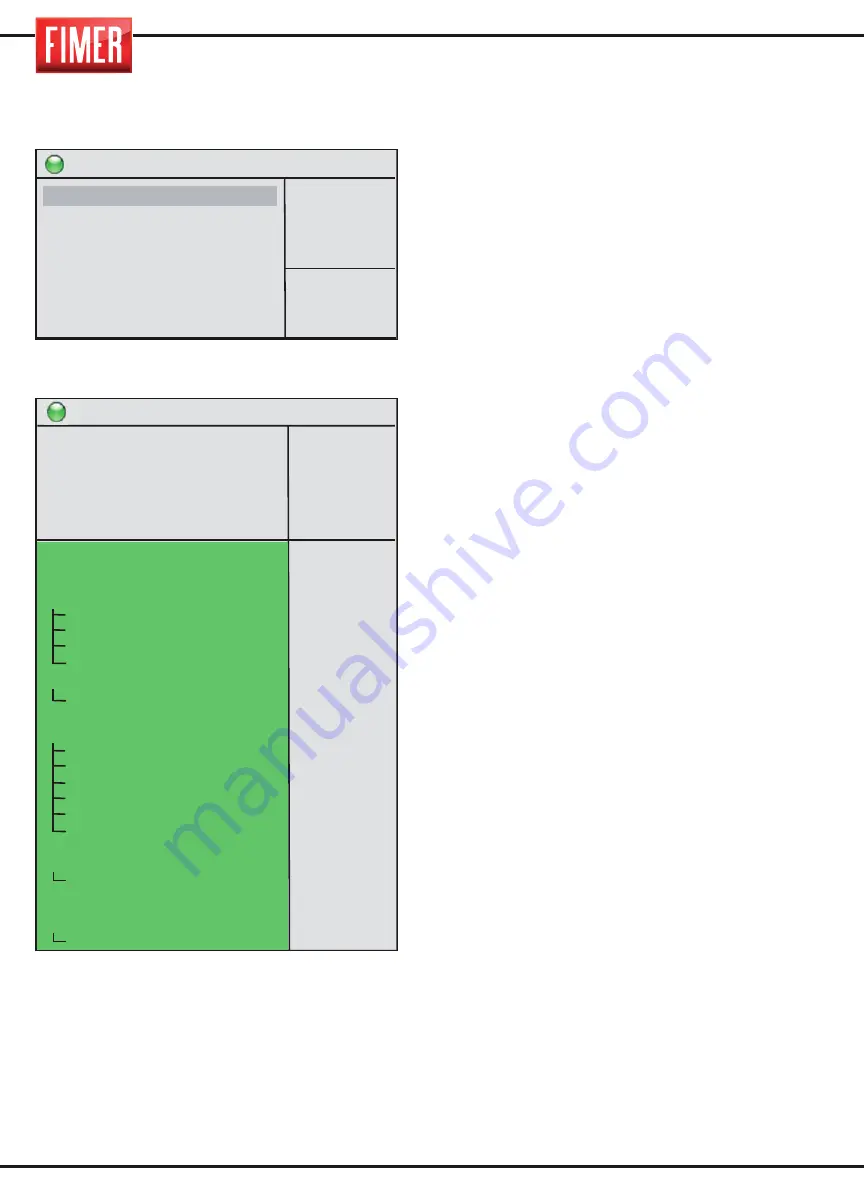

Once the type of wire has been selected

(using switch 10), the settings page for the

welding wire diameter will appear.

Selecting this option will take you to the

welding screen:

ADJUSTMENTS AND SETTINGS:

Button 10 adjusts the welding settings on the

screen:

Voltage:

Used to vary the basic voltage

used for welding.

Deposit:

Used to modify the deposit of filler

material (wire speed) compared to the

predetermined synergic value.

Inductance:

Used to modify the speed of

variation of the welding current to obtain a

harder arc (low values) or softer arc (high

values.

DSF:

Used to activate (ON) or deactivate

(OFF) the mode at two levels, in other

words the continual switching between

two different levels of welding current

L1 span:

When the two level mode is active

this function is used to set the duration of the

first current level.

L2 span

: When the two level mode is active

this function is used to set the duration of the

first current level.

L2 amplitude:

When the two level mode is

active this function is used to set the second

current level (L2) compared to the current set

(level L1)

L2 voltage:

When the two level mode is

active this function is used to modify the

voltage of the second level (L2)

independently of the voltage of the L1 level

(arc length parameter)

2t-4t-4bilevel:

Used to set the operating

mode to 2 times or 4 times.

2t:

In 2 time operating mode the machine

welds for the entire time the torch button is

held down.

4t:

In 4 time operating mode pressing the

torch button once starts the weld and

pressing it a second time ends the weld.

4bi:

This operation is similar to the 4t mode

with the only difference that pressing the

torch button for short periods (< 1s) during

welding causes the passage of the current

from the first level I1 to the second level I2;

holding the button down (> 1s) causes the

start of the end of the weld.

2nd level:

used to set the value of the

current relative to the second power level,

active when the value of the 2t-4t-4bilevel

parameter is set to 4bi.

START

BACK

OPTIONS

0,6mm

0,8mm

1,0mm

1,2mm

Select wire diameter

MIG-MAG

S.A.S.

Fe

Ready to weld

START

BACK

MEM +

OPTIONS

80

A

23,2

V

>

MIG-MAG

S.A.S.

Fe

0,6mm

voltage

deposit

inductance

DSF

L1 span

L2 span

L2 amplitude

L2 voltage

2s-4s-4bilevel

2nd level

start/End level

Start current

Start time

Ls->L1 slope

L1->Le slope

End current

End time

pre gas time

burnback

0,0v

0,0m/’

0

OFF

0,3s

0,3s

60%

0,0v

2t

80%

OFF

125%

0,0s

0,0s

0,0s

80%

0,0s

0,1 s

post gas time

2,0 s

0,0 s

remote

min level

OFF

0

cooling unit

OFF

10,5m/'

1,8mm

spot welding

pause

0,0s

0,0 s

Summary of Contents for King 350

Page 4: ...TARGA DATI NOMINAL DATA LEISTUNGSCHILDER PLAQUE DONÉES PLACA DE CARACTERÌSTICAS ...

Page 39: ...3 ...

Page 40: ...4 ...

Page 71: ...3 ...

Page 72: ...4 ...

Page 103: ...3 ...

Page 104: ...4 ...

Page 135: ...3 ...

Page 136: ...4 ...

Page 165: ...NOTE ...

Page 166: ...NOTE ...

Page 168: ......