MIG-MAG WELDING

19

5

Attention:

Before starting the wire installation steps, always remove the gas nozzle/diffuser and the wire

guide tip from welding torch. Disconnect the electrical supply cable.

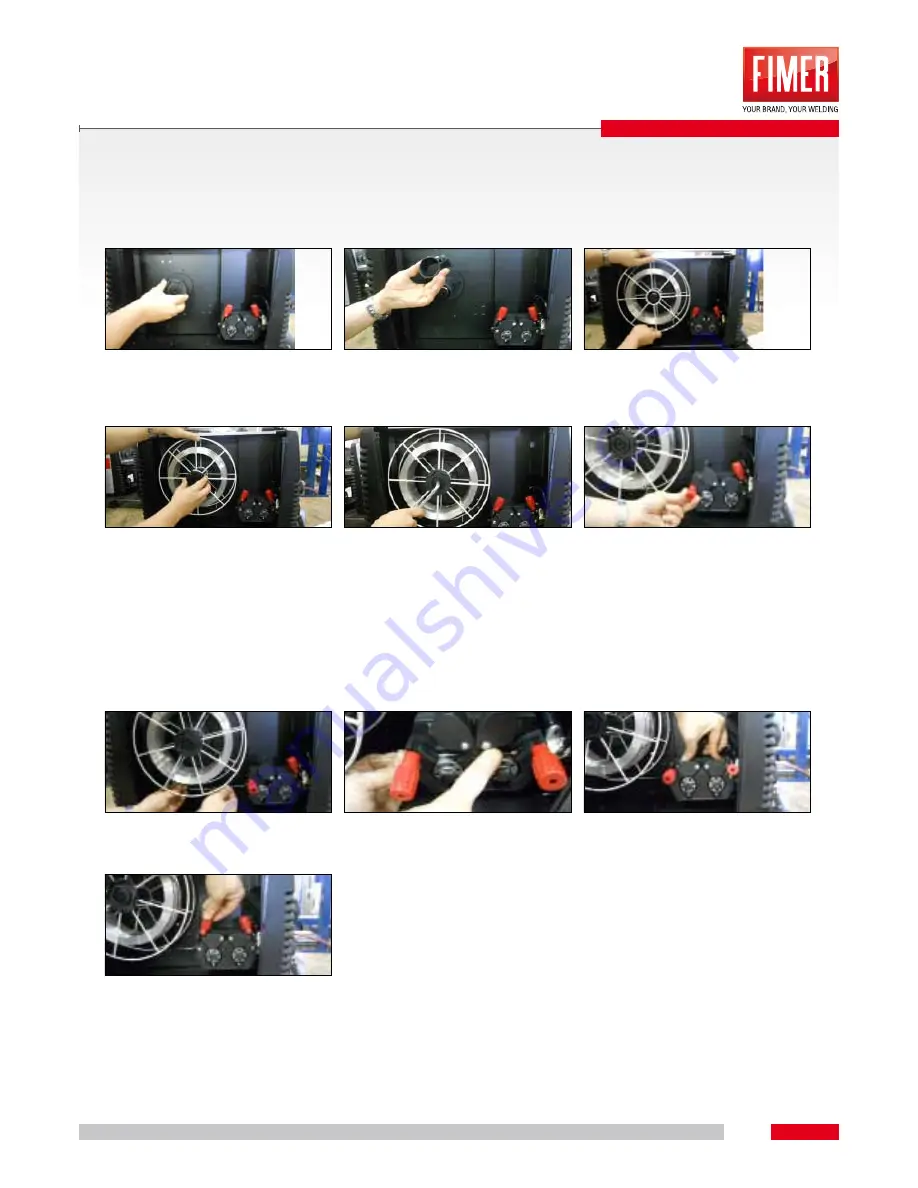

A

B

C

Unscrew the knob placed at the center of

the welding wire roll.

Eventually remove the spacer depending

on the roll’s dimensions.

Remove the plastic protection of new roll

and place it on the defined support.

D

E

F

Re-assemble the knob.

Pay attention to the hex (M8) placed in

the center of roll support which is the fric-

tion system of wire.

Screw in the hex to obtain a good friction:

If You fix hard the friction is excessive

and arrests the normal unrolling of the

roll. Otherwise a low braking makes the

wire unrolls itself accidently at the end of

welding.

Unscrew the knobs of the wire feeder

group and let them turn. In this way they

will lift the upper wire feeders.

G

H

I

Insert the wire into the wire feeder engi-

ne capillary tube .

Let the wire flows under wire feeder rolls

until the entrance of euro connector.

Reduce the upper rolls and close the

wire pressure regulation plastic knob.

L

Tight carefully the knob. If it is too narrow the wire will block; otherwise if it is too

slack it won’t be able to drag the wire.

Repeat the operation also for the second milled knob.

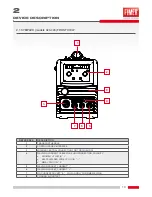

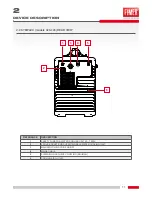

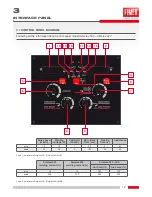

Summary of Contents for SYMPLEX 320

Page 1: ...SYMPLEX 320 SYMPLEX 420 Ed 2014_11_11 INSTRUCTION MANUAL 910 100 512GB REV00 ...

Page 5: ...SYMPLEX 320 SYMPLEX 420 ...

Page 32: ...32 11 NOTE ...

Page 33: ...33 11 NOTE ...

Page 34: ...34 11 NOTE ...