MIG-MAG WELDING

20

5

5.4 ROLLS REPLACEMENT

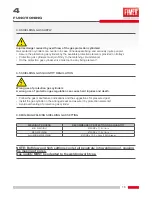

Danger of injuries due to welding wire escaping from welding torch!

•

Welding wire can quickly escape from welding torch and cause injuries to face, eyes and other

body parts!

•

Never point the welding torch to Yourself or to other persons!

•

Danger of injury due to the presence of movable parts!

•

Wire feeder devices are equipped by movable parts which can drag hands, hair, clothes or tools

with the risk to injury persons!

•

Never touch components or rotary elements during motion!

•

Lay the torch beam tubes in stretch position

•

Unlock and overturn pressure unit (tension unit with pressure rollers automatic overturn themselves

to above)

•

Carefully unroll the welding wire from roll and insert it into capillary tube or into the Teflon core

equipped by guide tube through the wire entry junction on feeding rolls slots and through guide

tube.

•

Push below again the tension unit with pressure rollers and get up pressure units (electrode wire

must be placed into the feeding roll slot)

•

Contact pressure on unit regulation nuts must be set to allow welding wire can be supplied but also

it can slide when wire roll is locked!

•

Mainly front contact rolls pressure (during progress direction) must be more elevated than back

rolls.

•

Push insert button until wire electrode comes out from welding torch.

Summary of Contents for SYMPLEX 320

Page 1: ...SYMPLEX 320 SYMPLEX 420 Ed 2014_11_11 INSTRUCTION MANUAL 910 100 512GB REV00 ...

Page 5: ...SYMPLEX 320 SYMPLEX 420 ...

Page 32: ...32 11 NOTE ...

Page 33: ...33 11 NOTE ...

Page 34: ...34 11 NOTE ...