21

IT

AL

IA

NO

31. POWER ELECTRICAL CONNECTOR

(cable bundle) (separate trolley)

32. GASE TUBE CONNECTION

(cable bundle)

(separate trolley) (Black)

33. CONNECTION FOR LIQUID COOLING

(separate trolley) (Red)

34. CONNECTION FOR LIQUID COOLING

(separate trolley) (Blue)

35. ELECTRICAL CONNECTOR FOR THE

SIGNALS

(cable bundle) (Base)

36. ELECTRICAL CONNECTOR FOR THE

POWER

(cable bundle) (Base)

37. CONNECTION FOR LIQUID COOLING

(Base) (Blue)

38. CONNECTION FOR LIQUID COOLING

(Base) (Red)

5. INSTALLATION OF THE WELDING

WIRE

Follow the instructions below to install the weld-

ing wire (refer to

Figure 2A

).

Attention: before installing the welding wire,

always remove the gas nozzle (

Fig. 3A

) and

wire-guide tip (

Fig. 3B

) from the welding torch.

1.

Disconnect the power cord from the mains

outlet (

22 of Fig. 2 and 4C

).

2.

Unscrew the knurled knob positioned in the

middle of the welding wire spool (

23 of Fig. 2

)

and, if necessary, remove the used spool.

3.

Remove the plastic wrapper from the new

spool and place the spool on the special spool

holder (

23 of Fig. 2

). Reassemble the knurled

knob. The allen screw

(M8)

positioned under-

neath the knurled knob forms the braking system

of the wire spool. Tighten the allen screw in order

to obtain the best braking result. Too much pres-

sure may cause excessive braking which in turn

may block the wire-feed motor. Too little pressure

may not allow the wire spool to immediately stop

at the end of the welding.

4. TM 230, TM 260:

Unscrew the knob of the

wire-feed unit (

27 of Fig.2A

) and lift the upper

feed roll (

29 of Fig. 2A

).

TM 300, TM 350:

Unscrew the knob of the wire-

feed unit (

27 of Fig.2A

) and turn outwards. This

will lift the upper feed rolls (

29 of Fig. 2A

).

TM 360W, TM 420W, TM 500W, TM 650W:

Unscrew the knobs of the wire-feed unit and turn.

This will lift the upper feed roll (

29 of Fig. 2A

)

Remove any wire left over from the previous

welding.

5.

Insert the wire into the little in-feed tube

(26 di

Fig. 2A)

of the wire-feed motor and let it slide

under the wire-feed rolls.

6.

Lower the upper rolls

(29 of Fig. 2A)

and tight-

en the plastic knob

(27 of Fig. 2A)

of the wire

pressure regulator.

Tighten slightly. If tightened too much, the wire

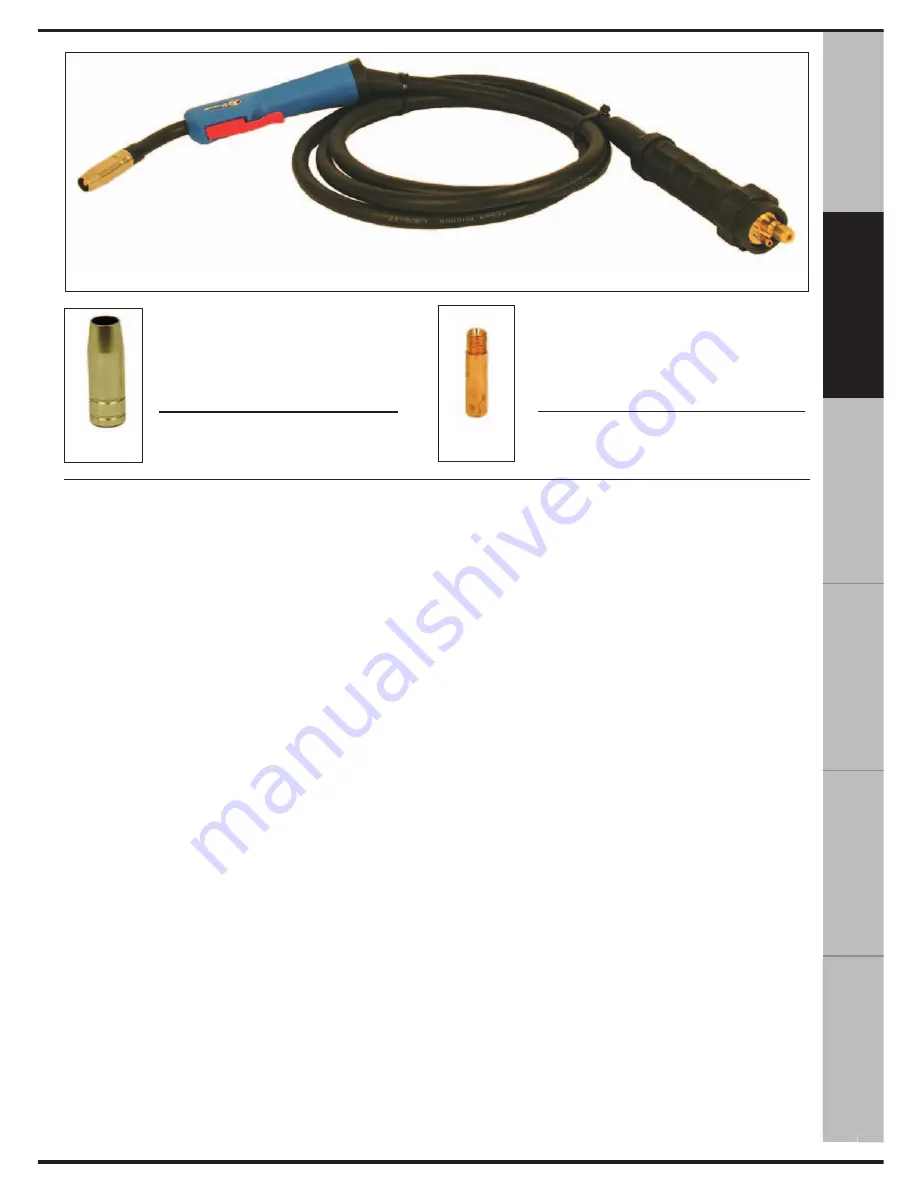

Fig.3A

Fig.3B

GAS NOZZLE

WIRE-FEEDER GUIDE

Fig.3

TORCH CABLE

EN

G

LI

SH

ES

PA

ÑO

L

РУ

СС

КИ

Й

FR

AN

ÇA

IS

DE

UT

SC

H