23

IT

AL

IA

NO

4.

Connect (if present) the quick connector (

38 of

Fig 4B

) of the red tube to the quick coupler (

38

of Fig 4C).

5.

Connect (if present) the quick connector (

37 of

Fig 4B

) of the blue tube to the quick coupler (

37

of fig 4C).

6.

Connect the gas hose (

Fig 4B

) to the cylinder

(Fig 5)

by carefully following the instructions out-

lined in

Paragraph 7

.

7.

Take hold of the other end of the cable bundle

(

Fig 4A

).

8.

Connect the power electrical connector (

31

of Fig 4A

) to the appropriate coupler (

31 of

Fig 4C).

9.

Connect the signal connector (

30 of

f

ig 4A)

to

the appropriate coupler (

30

of

Fig 4c)

.

10.

Connect the quick connector of the black gas

hose

(32 of Fig 4A)

to the appropriate coupler

(32 of Fig 4C).

11.

Connect the quick connector of the red tube

(33 of Fig 4A)

to the appropriate coupler

(33 di

Fig 4C).

12.

Connect the quick connector of the blue tube

(34 of Fig 4A)

to the appropriate coupler

(34 of

Fig 4C.

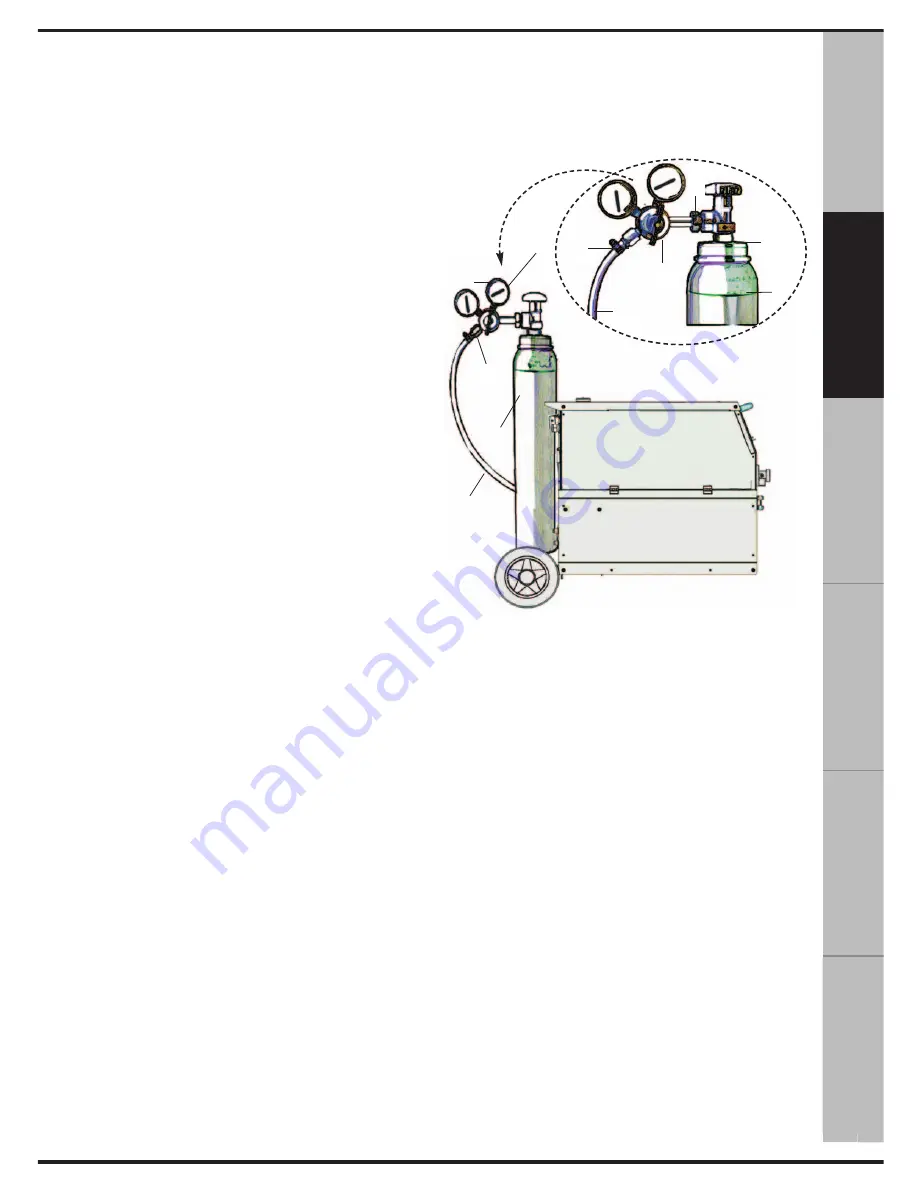

7. CONNECTION OF THE GAS CYLIN-

DER AND REGULATOR (see Fig 5)

1.

Connect the pressure regulator

(2)

to the gas

cylinder

(3)

.

Tighten the connecting nut

(6)

of the regulator

(2)

to the cylinder

(3)

.

Do not over-tighten because this may damage

the valve

(1)

of the cylinder

(3)

.

2.

Connect the gas hose

(4)

to the regulator

(2)

by securing it with a tube clamp

(5).

3.

Make sure the gas hose is correctly connect-

ed to the welding machine.

4.

Open the valve

(1)

of the gas cylinder

(3)

.

Press the torch button and make sure the gas

flows correctly.

Attention:

The cylinders contain highly pressurized

gas. Handle with care. Improper handling could lead

to serious accidents. Do not place the cylinders on top

of each other and do not expose to excessive heat,

flames or sparks. Do not allow the cylinders to strike

against each other. Contact your gas supplier for more

information on the use and handling of the cylinders.

Attention:

Do not use the cylinder if you find

oil leaks, grease or damaged parts.

Immediately contact your gas supplier if these

conditions exist.

8. MIG TORCH

It is recommended to periodically check the con-

dition of the welding torch. In particular, check

the gas nozzle

(Fig 3A)

and wire-guide tip

(Fig

3B)

. These parts must be kept clean and intact.

Replace the wire-guide when the wire does not

run smoothly.

9. PREPARING FOR THE WELDING

1.

Connect the welding machine to the mains

power.

2.

Make sure the polarity of the torch and ground

cables are positioned correctly.

3.

Connect the ground terminal to the workpiece,

making sure the contact is good.

Fig. 5

2

5

3

4

5

4

3

1

2

6

1

РУ

СС

КИ

Й

ES

PA

ÑO

L

FR

AN

ÇA

IS

DE

UT

SC

H

EN

G

LI

SH