8

(LED 22 on) or pulsed

TIG mode (LED 23 on).

25. WELDING CURRENT KNOB.

Further Function: Turning this knob, while

using button 14 and LEDs 3 to 10, the

welding parameters can be set.

26. LOCAL / REMOTE SELECTOR:

Local (LED 27 off) or Remote (LED 27 on)

use of the welder can be selected pressing

this button.

When in local use the welding current is set

turning knob 25.

During remote use the welding current is set

using a remote unit (optional accessory).

27. REMOTE USE INDICATOR

28. BALANCE KNOB:

TIG AC welding:

The balance of the DC

component of the AC output welding current

can be set using thes Knob.

TIG DC/MMA welding:

Not used

29. Balance Current Confirmation:

TIG AC welding:

This lights up for app. 4

seconds at each setting selected using of

Knob 28.

MMA + TIG DC welding:

Not used

30. Direct polarity indicator

31. Reverse polarity indicator

32. AC mode indicator

33. Polarity selector:

Repeatedly pressing

this button alternates the output polarity .

MMA Mode:

switch between direct polarity

(LED 30 ON) (usual selection) and Reverse

polarity (LED 31 ON)

TIG Mode:

switches between Reverse

polarity DC mode(LED 31 ON) and AC

mode (LED 32 on).

34. Air-intake grills

35. Welding front socket

MMA welding:

Electrode clamp

TIG welding:

Welding Torche

36. Remote Control Connector

MMA welding:

Using a dedicated (optional)

accessory, the welding current can be

remote adjusted.

TIG welding:

A “start” or “stop” command is

relayed from the torch to the unit.

If a welding pedal (optional accessory) is

used, a suitable current level command is

also sent. (In the latter case, the torch button

is automatically disabled.).

37. Gas Hose Connector:

MMA welding:

Not used

TIG welding:

Torch hose connection.

38. Earth Clamp

MMA welding:

Earth Clamp

TIG welding:

Earth Clamp

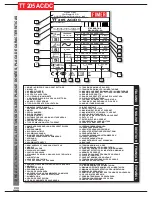

FIGURE 2:

39. Fuse

40. ON/OFF SWITCH

Switches ON or OFF

the unit

41. Power supply cable: Input cable

provided with plug.

42. GAS INPUT:

(Paragraph 5)

MMA welding:

Not used

TIG welding:

elding torch hose connection.

43. Liquid-Cooling System Connector

(optional accessory):

Beware !!

The connector uses dangerously high

voltage: NEVER use it for any other use than

as described in this Manual.

3. CONNECTION TO POWER SUPPLY

Before plugging the unit in, check the power

supply voltage, phase and voltage

frequency.

The permissible voltage is shown in the

“Technical Specification” chapter of this

manual and on the unit nameplate. Ensure

the welder is earthed appropriately. Also

check that the plug provided with the unit is

compatible with the local power grid socket.

Make sure that the power supply is sufficient

to operate the welder.

The types of power supply protection

devices to be used are listed in the

“Technical Specification” section of this

manual.

The power cable supplied with the welder

should not be extended but, if that becomes

necessary, either an identical or greater

cross-section cable should be used

according to the final cable length. The

TT165 AC/DC and TT205 AC/DC models

Summary of Contents for TT165 AC/DC

Page 1: ...InstructionManual TT165 AC DC TT205 AC DC TT165 AC DC TT205 AC DC ...

Page 4: ......

Page 5: ...TT165 AC DC TT205 AC DC ...

Page 10: ...X ...

Page 12: ......

Page 30: ...20 NOTE ...

Page 32: ...Cod 910 100 333GB REV00 ...