15

6.3 AC - TIG Welding (LED 22, 23 and 32

Fig.1 ON) Select this mode pressing

button 24 repeatedly until LED 32

(normal TIG welding) or LED 33 (pulsed

TIG welding) of Figure 1 lights up.

Check the Led (31 - Fig. 1) is ON.

6.3.1 Description

Argon gas welding using unmeltable

tungsten electrodes (often called

TIG:Tungsten Inert Gas welding) is a

process by which heat is generated by an

arc when a non-consumable electrode

makes contact with the workpiece. Welding

occurs when the edges of the workpiece

are molted and filler metals in rod form are

used to fuse the materials together.

TIG welding can be used in all work

positions and can be applied to even very

thin metal sheets.

It is a procedure that provides easy arc

control, a powerful concentrated heat

source and full control of the amount of filler

used. It is particularly useful when accurate

welding is required on a wide range of

thicknesses, when welding in awkward

positions or where deep fillings are required

on pipes, for instance. In TIG mode a

variety of materials can be welded : ferrous

materials, nickel alloys, copper, titanium,

magnesium etc. It is not, however,

advisable for aluminium.

Before welding the following settings must

be programmed:

1)

Arc generation mode (Lift or HF)

2)

Welding mode (2T, 4T or 4T Bi-Level)

3)

Welding procedure (Normal or Pulsed)

6.3.2 Arc Generation Mode (Lift or HF).

The arc can be generated either by

touching the electrode to the workpiece (Lift

mode) or by approaching the torch to torch

to the workpiece (HF mode).

Lift

generation

minimises

electromagnetic disturbance and weld

pool pollution.

To select Lift mode, press button 20 (Fig. 1)

repeatedly until one of the following occurs,

as appropriate :

Led 16 on:

Lift mode for 2T welding

Led 17 on:

Lift mode for 4T welding

Led 17 and 15 ON:

Lift mode for 4T Bi-

Level welding

HF Arc Generation is easy and

minimises electrode tip damage.

To set HF mode, press button 20 (Fig.1)

repeatedly until one of the following occurs,

as appropriate :

Led 18 ON:

HF arc generation for 2T

welding.

Led 19 ON:

HF arc generation for 4T

welding.

Led 19 and 15 ON:

HF arc generation for

4T Bi-Level welding.

6.3.3 Welding Mode Selection (2T, 4T or

4T Bi-Level).

The welder’s behaviour and the welding

results differ according to the mode

selected (2T, 4T r 4T Bi-Level).

2T Mode

To select this mode press button 20 (Fig.1)

repeatedly until one the following occurs, as

appropriate:

Led 16 ON:

2T welding (Lift-Arc

generation).

Led 18 ON:

2T welding (HF Arc generation)

The torch will continue welding until the

torch button is released.

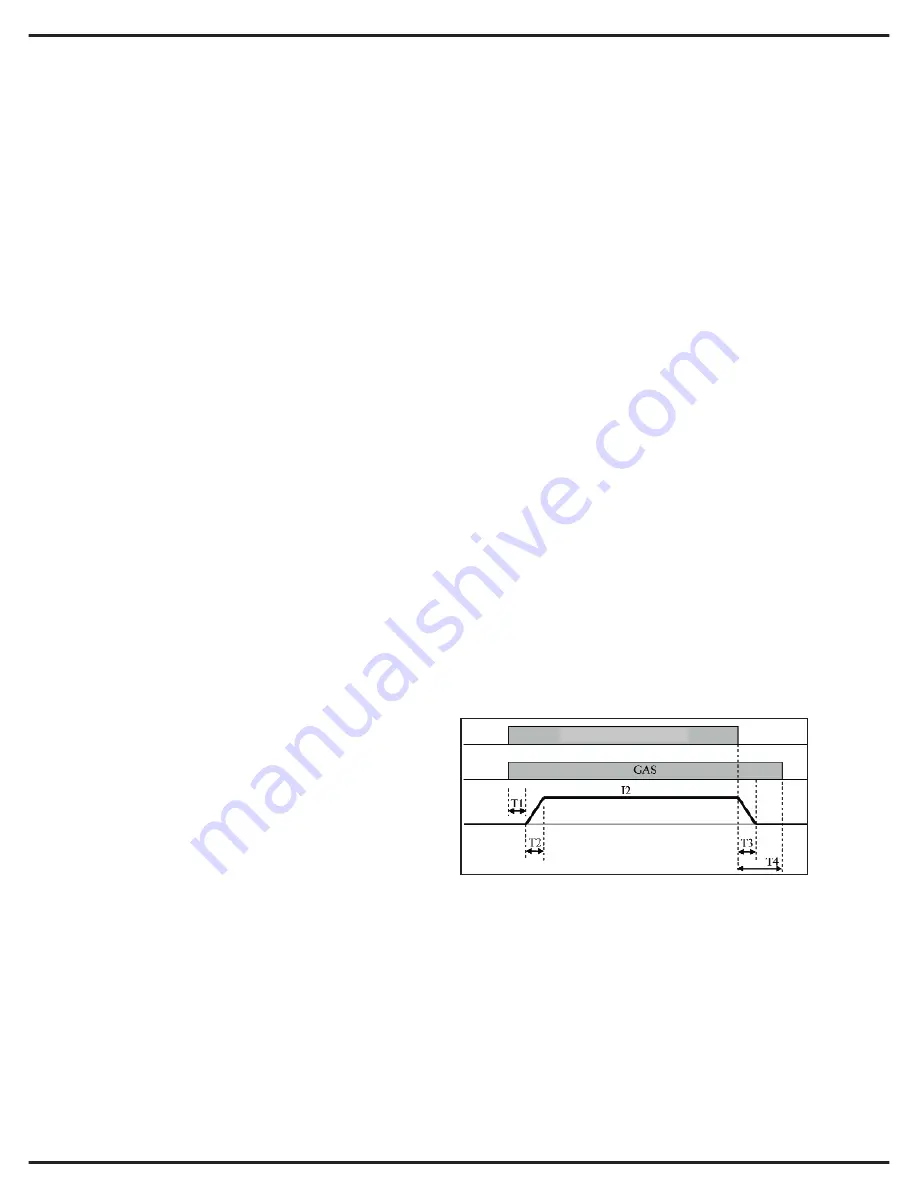

Fig. 5

Figure 5

shows exactly what happens

when the torch button is pressed.

BUTTON PUSHED

Summary of Contents for TT165 AC/DC

Page 1: ...InstructionManual TT165 AC DC TT205 AC DC TT165 AC DC TT205 AC DC ...

Page 4: ......

Page 5: ...TT165 AC DC TT205 AC DC ...

Page 10: ...X ...

Page 12: ......

Page 30: ...20 NOTE ...

Page 32: ...Cod 910 100 333GB REV00 ...