Vibrator

1

A particular feature of this newly developed vibrator is its

easily calibrated impact interval of from 0.5 to 200 impacts per

minute.

The impact force can be set to three levels.

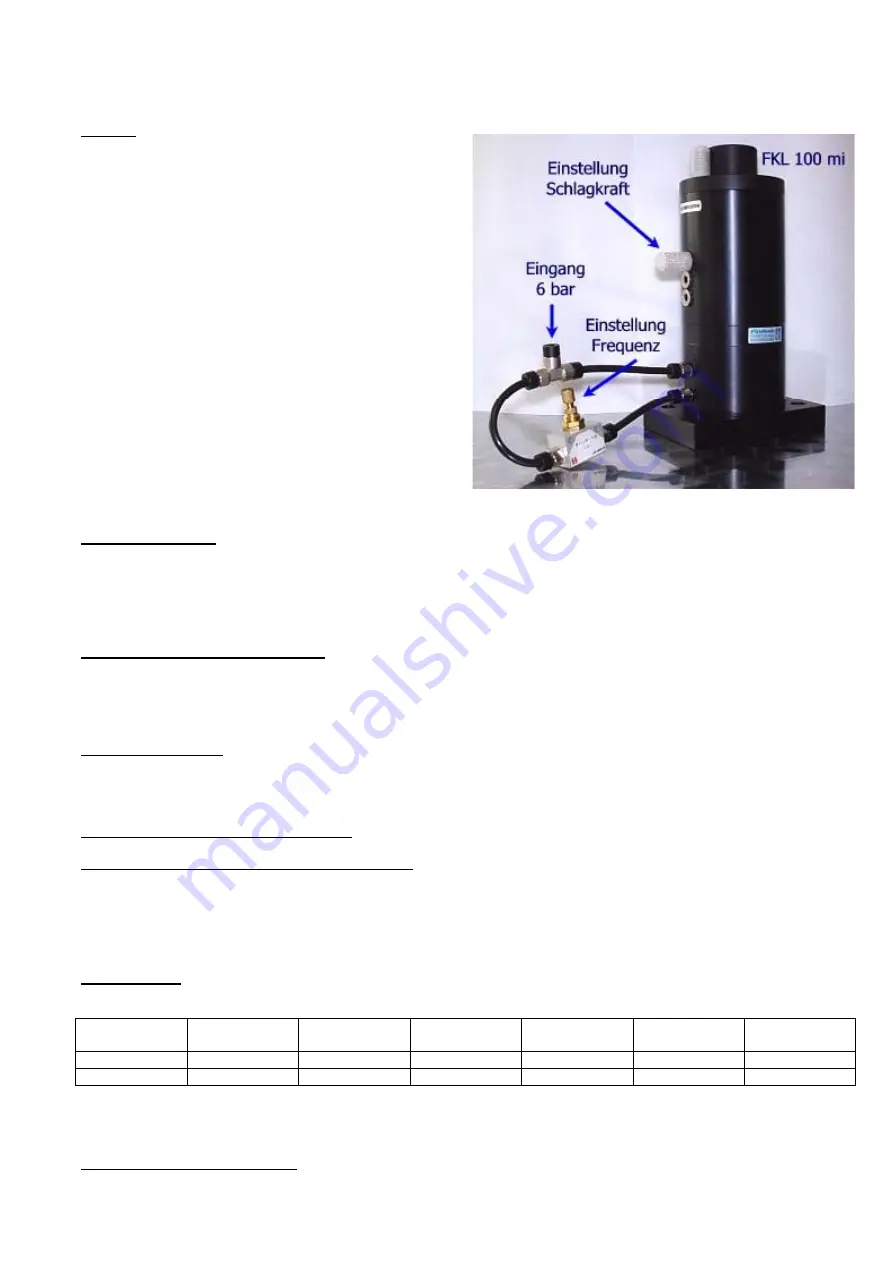

Pneumatic impact force: Via the compressed air’s exhaust

channel.

Upper exhaust channel open = maximum force

Lower exhaust channel open = minimum force

Pneumatic frequency:

By means of a throttle valve

(included in supply specification)

The vibrator is supplied with a base plate, which serves to

attach it and to transmit the impacts it generates.

The vibrator’s housing and base plate are made from

aluminium. The impact plate (integrated into the base plate) is

made from shock-resistant special plastic material.

Areas of application

Compressed air interval vibrators can be employed for knocking off material that has become attached to the inner surfaces of

containers (e.g. silos, hoppers, filter outlets, reactors and pipelines).

These vibrators can be used in wet surroundings and in those where there is a risk of explosion, or in the open air.

Construction and mode of operation

In the case of an FKL 100 mi, a piston is pushed against a spring by means of compressed air. Each time the piston passes the

compressed air outlet port, there is a rapid venting and it is shot under spring pressure against the impact plate contained within

the device. The piston valve then closes and the procedure is repeated at the speed set by means of the throttle.

Operating conditions

Reciprocating vibrators can be employed in dusty, wet or explosion-protected environments. Their piston seals are suitable for

oil free operation.

Standard installation for the FKL 100 mi

The drive mechanism is to be provided by the customer

Operation of the device can be controlled via a 3/2-way, normal/shut air valve. (Not to be confused with the interval, which is

set using the throttle valve supplied.) Hose of 6 mm diameter

The control mechanism can be by means of a:

- Process control system - Time lag relay - On/off switch

Technical Data

Pressure

Action / Impact

Impulse /

Impact

Weight Air

consumption

Frequency

Device

bars

Nm

Ns

kgs

litre / impact

impact / min.

FKL 100 mi

6 - 8

10 / 20 / 40

5 / 7.5 / 10

4.45

0.5 – 1.1

0.5 - 200

The FKL 100 mi can be employed for wall thicknesses of up to 5 mm

1

Set impact force; Inlet 6 bars; Set frequency

Operating instructions for FKL 100 mi

EM

02.07.2003

4300.00