6.

7.

8

9

10

11

Observe the display for true rms current flow. Any

with

phases, indicates the

presence of harmonic

Press

Hz pushbutton measure the frequency of

neutral wire.

Reading

indicates the frequency of the

dominant current flow (in

of harmonic current flow,

reading in a

System).

To freeze the digital display, press the HOLD

pushbutton.

To measure half-cycle peak amperes, press the SOFT

CREST pushbutton twice (PEAK displayed). A

other than 1.414 an

of harmonic

current

. .

To

readings and

view maximum,

and

values, press the MIN MAX pushbutton.

To

RECORD, press the MIN MAX pushbutton for

2

seconds.

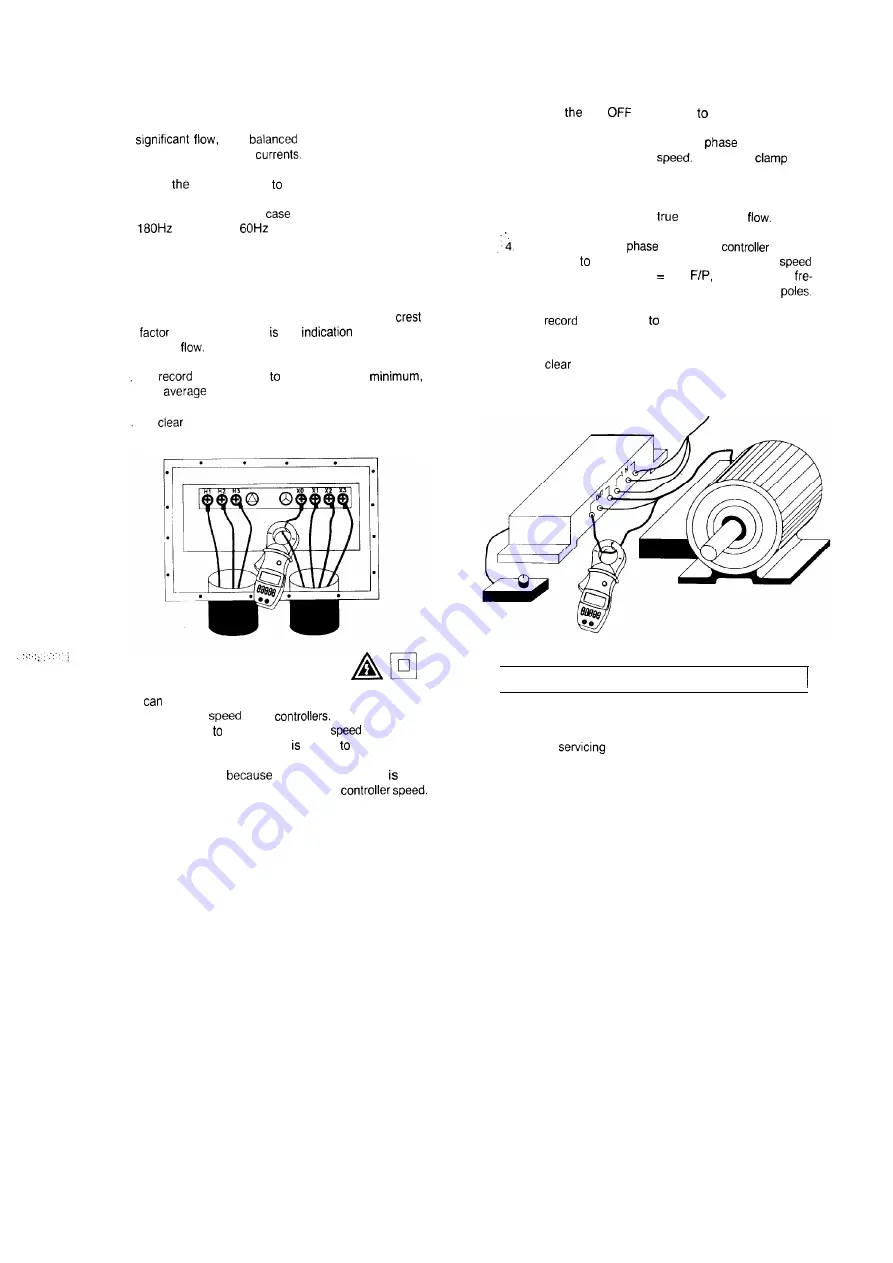

6.5 Adjustable Speed Motor Controllers

You

measure input current, output current and frequency

of the adjustable

motor

The output current

frequency is used calculate the rotating

of the motor,

while input current frequency

used

measure the

frequency of the power line. The frequency of the output

current is important

the voltage frequency often

meaningless for the calculations of motor

24

1.

2.

3.

5.

6.

Press

ON

pushbutton turn on this Meter.

Clamp around an input or output

(as

required),

and run motor at desired

Be sure the

jaws

are securely closed, or measurements will not be

accurate.

Observe the display for

rms current

Measure an output

of the motor

and use

Hz mode measure frequency. Nominal motor

is calculated from RPM 120

where

F

is the

quency measured, and

P

is the number of motor

To

readings and view readings, press the MIN

MAX pushbutton.

To

RECORD, press the MIN MAX pushbutton for

2

seconds.

7. Maintenance and Calibration

7.1 Maintenance

Repairs or

should only be performed by qualified

personnel.

25

Summary of Contents for FINEST 135

Page 16: ......