4

Ⅳ

、

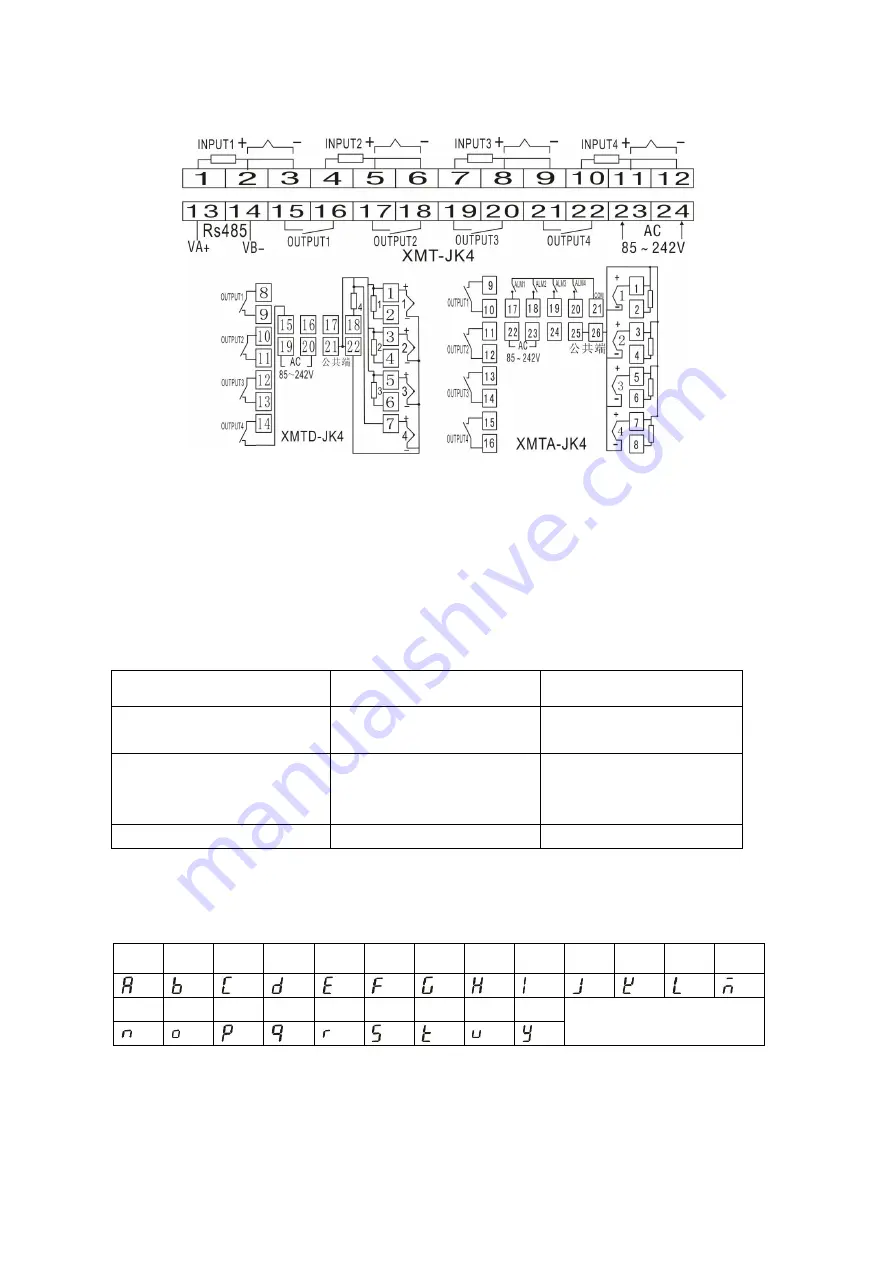

connection scheme(consult)

Notice:

The meter's signal input used to isolate type sensor, or that may affect the meter's

measurement.

Ⅷ

、

Fault Analysis and Clearance

XMT*-JK408 Series temperature controller adopt advanced production process, and have the

strict test before leaving factory, it improve the reliability of the meter .The usual fault caused by the

wrong operation or parameter setting. If you find the fault couldn’t be cope with, please record it,

and contact with the agent or us. Sheet 8-1 is the usual fault of XMT*-JK408 series temperature

controller in the daily application

:

Sheet8-1 Common fault disposal

Fault symptom

Analysis of causes

Disposal measurement

Abnormal power

1

、

Poor contact of power cord

2

、

Power switch without lose

Check the power

Signal display do not correlate

with the facts.

(

display ‘HH’or

‘LL’

)

1

、

Sensor model mismatch

2

、

Wrong signal connect ion

1

、

Check sensor model and meter

interior input parameter

2

、

Check signal wire

Abnormal control output

Wrong connection of output wire

Check output connection

Note:

Our company will continue to improve product technology, design specification. If

change, please subject to the

material object, without notice.

Attached 1

:

Statement of meter’s parameter attention letter and English letter

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

Y

www.finglai.com