1

2.2

B

A

MEGA SD - Cod.197DD8100

GB

START-Up AND OpERATION

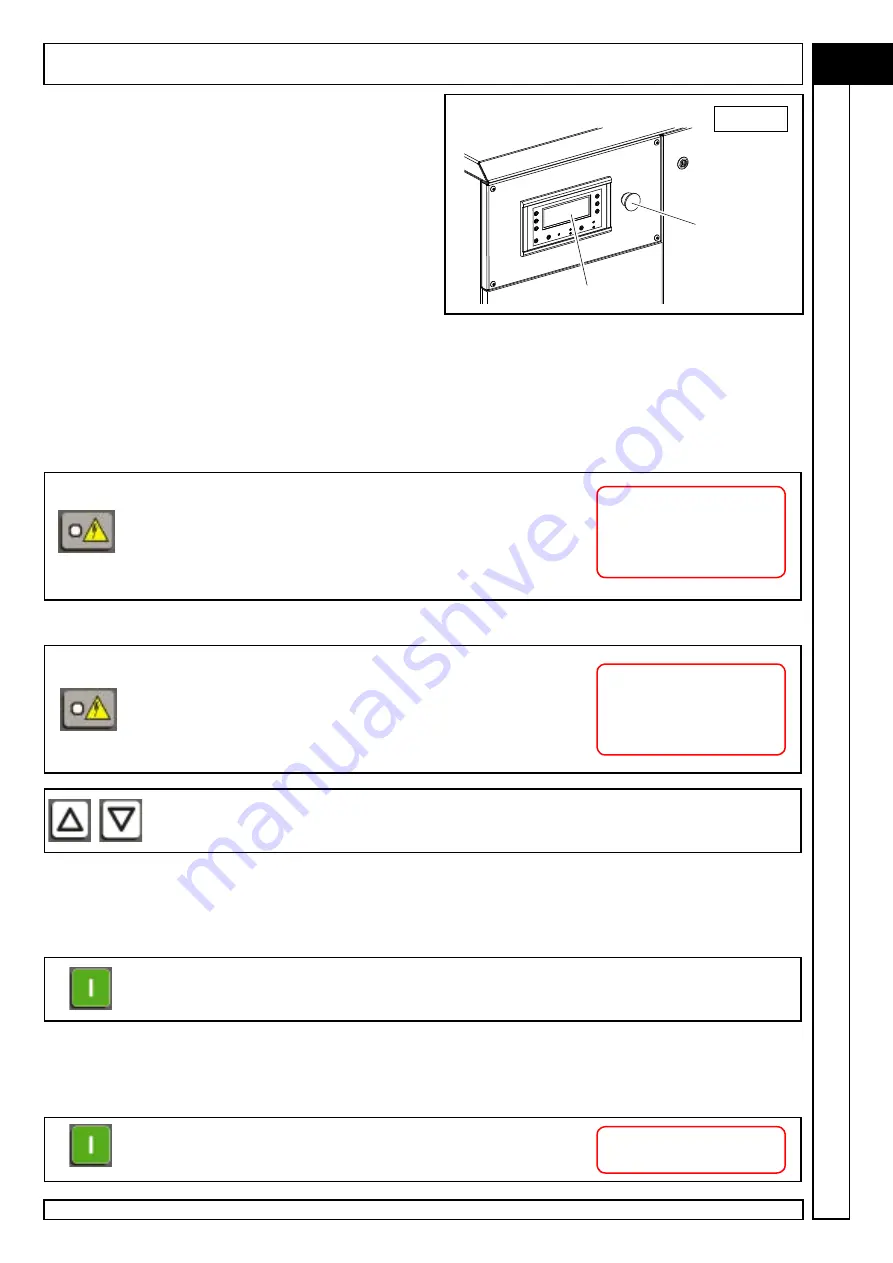

2.2 - EMErGENCY STOP BUTTON

The red EMERGENCY STOP button b stops the machine

immediately.

Use this button for emergencies only in conditions which

appear hazardous for the operator or for the machine

(see

“Compressor emergency STOP” below).

2.3 - STArTING AND STOPPING THE COMPrESSOr

STArTING the compressor

when the machine is switched on (powered) the control unit starts the initial sequence

and prepares to control the compressor.

According to the sequence, with the

LP Ied ON steadily,

the following screen page must

be shown on display DL:

This screen page indicates:

LINE 1 abbreviation of the control unit.

LINE 2 /

LINE 3 software version which may differ from that indicated.

LINE 4 serial number of control unit, different for each machine.

After a few seconds, the display shows the main screen page:

This screen page indicates:

LINE 1 indication of network pressure.

LINE 2 indication of compression temperature of air-oil mixture.

LINE 3 messages about operating conditions.

LINE 4 hour and date, information menu access, tree menu access,

quick language change message.

To change the language use the K5 and K6 keys.

If the compressor is operating, LINE 1 and LINE 2 always show the above information.

Particular indications (error messages), additional information or the information

of the management menu are displayed on LINE 3 and on LINE 4.

If LINE 3 shows “Ready for start”, the compressor can be started.

The compressor is started by pressing the green K1-START key.

At this point, the compressor may:

a) start, displaying the messages referring to the start and functioning phases.

b) prepare to start with the following message.

In this case, network pressure is above the minimum threshold value

set; the compressor will start automatically in the case of a request for

air from the network.

SC03

Vers.Soft.: 1.0.0.1

SIN: 000-00-01-00001

Pressure XX.X bar

Temperature XXX °C

ready for start

0:40 MON 25/05/2009

Stand by auto start

hour-date