8

6

7

MIN.

MAX.

B

A

D

C

G

F

F

E

MEGA SD - Cod.197DD8100

GB

MAINTENANCE

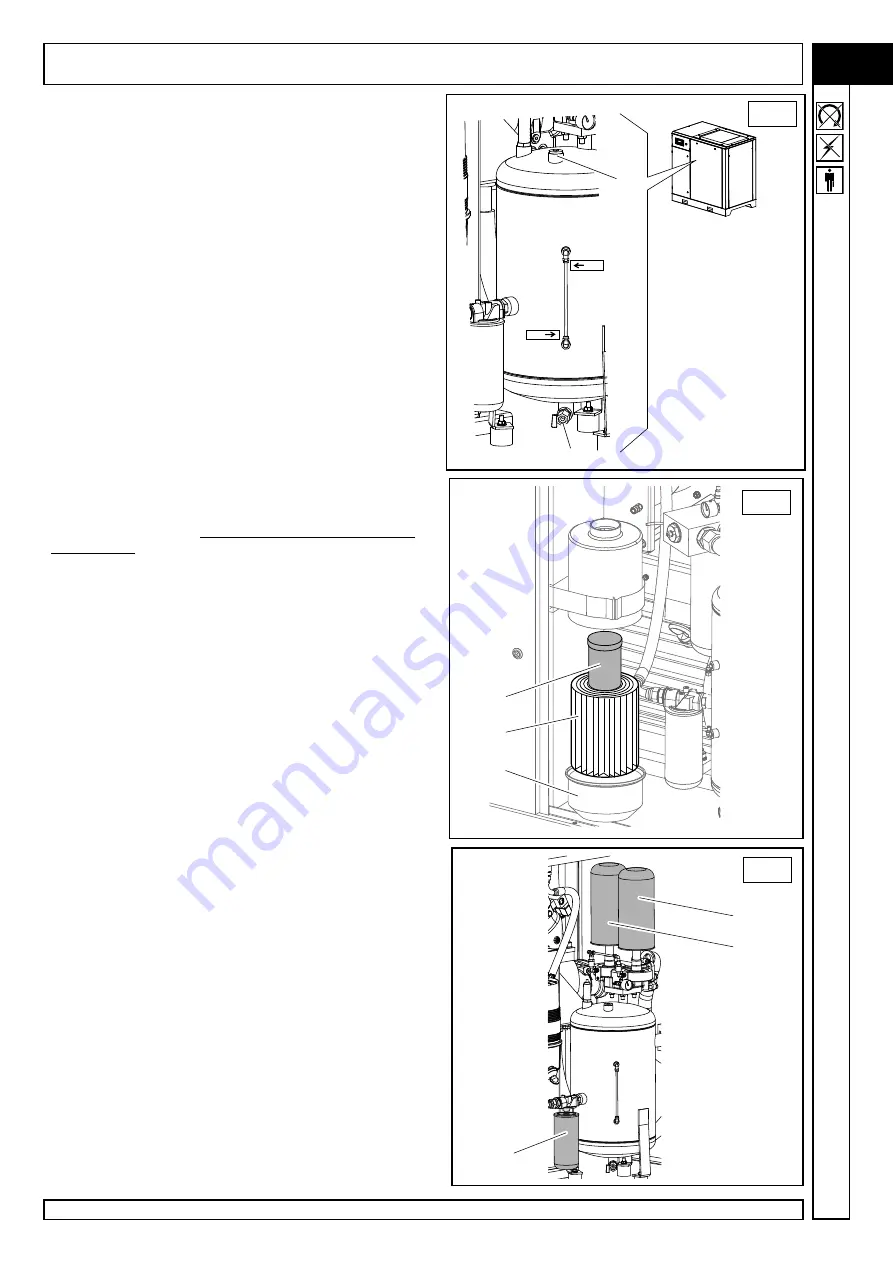

DrAIN CONDENSATE

(Fig. 6)

The oil/air mixture cooling is set at a higher temperature with

respect to the dew point of the air (under standard operating

conditions of the compressor). however, the condensate in the

oil cannot be fully removed.

blow off compressed air through cock

B

and then close it as

soon as oil begins to flow out instead of water. Check the oil

level and top up if necessary.

CONDENSATE IS A POLLUTING MIXTUrE!

It must not be

let into the sewage.

OIL CHECK AND TOP UP IF NECESSArY

(Fig. 6)

With the compressor off,

check the oil level by means of the

warning indicator positioned on the front panel 2.

If the level is under the minimum, remove the front panel and

refill through hole A. Quantity of oil for refilling from the min to

the max level = 3.5 litres.

use ONLY oil of the same type (RotEnergy Plus).

CLEANING/rEPLACING THE FILTErING

ELEMENT

(Fig. 7)

Remove the rear panel, unhook the clips and remove the cover

G. Extract the two filtering elements (primary element C) and

(security element D). Clean them using compressed air, acting

from the inside towards the outside.

Control, against the light, for the presence of splits: in this case

replace filters.

The filtering elements and the cover must be assembled

carefully, so as not to allow the passage of dust into the

compressor unit.

Never allow the compressor to function without the

filtering element.

CLEANING THE rADIATOr

It is recommended that in case of over temperature anomalies

and however, at least once a year that the radiator is

cleaned.

Proceed as follows:

• position a sheet of protective plastic under the radiant

pack;

spray (with a w detergent gun) from inside towards

the outside:

• check that the air flows correctly by means of the radiator.

rEPLACING THE OIL FILTEr

(Fig. 8)

with the compressor stopped, remove the front panel.

Alarm signal

At each change replace also the oil filter

E

, unscrew the old

filter and replace it. Always apply some oil on the edge of the

filter and on the seal before refitting manually the filter.

rEPLACING THE SEPArATOr FILTEr/

FILTErS (

Fig. 8)

-

50-60 HP

replacing of a filter

- 75

HP

replacing of two filter

with the compressor stopped, remove the front panel.

Alarm signal

The oil separator filter

D

cannot be cleaned, but must be

replaced.

unscrew filter manually (or if necessary use an appropriate

filter tool) turning it anti-clockwise.

After having slightly greased the oil separator filter seal and

O-ring, fit the new filter by turning clockwise.