10

9

MIN.

MAX.

B

A

C

E1

E1

E1

E2

E

E1

D

MEGA SD - Cod.197DD8100

GB

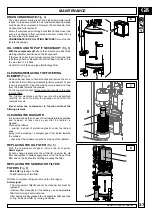

rEPLACING THE OIL

(Fig.9)

when the compressor is hot - above 70 °C, replace the oil.

Alarm signal

• Remove the front panel

• Connect the drain hose provided to cock b located at the base

of the separator tank.

• unscrew the plug from hole

A

, open the cock and allow the oil

to drain in to a container until draining is complete.

• Close cock b and withdraw the hose.

• Refill with new oil using hole

A

(quantity for complete refilling:

22,5 litres) and refit the plug.

To facilitate the filling, unscrew the cap C, then screw it again.

• Start up the compressor and allow to function for 5 minutes,

and then shut it down. Discharge all of the air and wait 5 minutes

before controlling the oil level. Top up, if necessary.

ThE EXhAuSTED OIL IS hIGhLY POLLuTANT! For its disposal

comply with the current laws on environmental protection.

• The first equipment oil is: RotEnergy Plus.

In the case of changing the type of oil, operate only for the

complete replacement. NEVER MIX DIFFERENT TYPES OF

OIL.

In this case, change also the oil filter and the separator filter.

MAINTENANCE

CHECKING THE TrANSMISSION BELT TENSION

(FIG. 10)

when the compressor is stopped, remove the panel

C

e the panel

D

and check the belt tension.

use a suitable measuring instrument that determines with precision the belt tension degree by means of a frequency measuring

device in order to perform this control.

Operate as follows:

• Place the microphone of the measuring instrument near to the

belt (about half way) and hit the belt with a wrench.

• Read the value detected by the instrument and if different from

the values indicated in the table (fig. 9A), adjust the tension:

Value higher = belt too tight

Value lower = belt too loose

Adjust by loosening the four bolts

E1

and adjust the tension

with the bolt

E2

.

After adjusting, tighten the bolts

E1

.

Check the frequency value again and if necessary, repeat the

operation.

rEPLACING THE TrANSMISSION BELT

(Fig. 10)

when the compressor is stopped, remove the panel C e the

panel

D

. Loosen the four bolts

E1

and act on the bolt

E2

loosening belt

E

until completely loose.

Remove the belt and replace it with a new one.

After replacing, check the belt tension as described

previously.

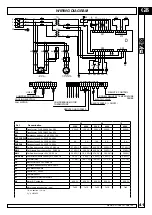

Belt tension

Power frequency (Hz)

50 Hz

60 Hz

Pressure

8 bar

10 bar

13 bar

8 bar

10 bar

13 bar

CV 50 (37 kW)

64

62

63

CV 60 (45 kW)

71

72

70

CV 75 (55 kW)

82

84

87

Tension frequency (Hz)