2

MEGA SD - Cod.197DD8100

GB

1) Electrical equipment

2) Front panel / Oil indicator level

3) Lid

4) Electric fan

5) Oil filter

6) Oil separator filter 50-60: N° 1

Oil separator filter 75: N° 2

7) Minimum pressure valve

8) Oil separator tank

9) Air filter

10) Air/Oil radiator

11) Electric motor

12) Control panel

13) Air intake outlet

14) Suction regulator

15) Screw compressor

UNPACKING AND HANDLING THE MACHINE

when delivered, compressor top is protected by cardboard packing.

wear suitable protective gloves and then cut outer straps and then remove cardboard from the top. Check the (outer) good

condition of the machine before moving the compressor. Visually check that no parts are damaged. Also ensure that all accessories

are available.

Lift the machine using a fork lift truck. Fit the anti-vibration elements into their proper seat and move the machine to the room

chosen for its location with maximum care.

Keep all packing materials at least for the warranty period for possible moving. In case of need, it will be safer for delivery to the

technical assistance dept.

Then, dispose of packing materials in compliance with current laws.

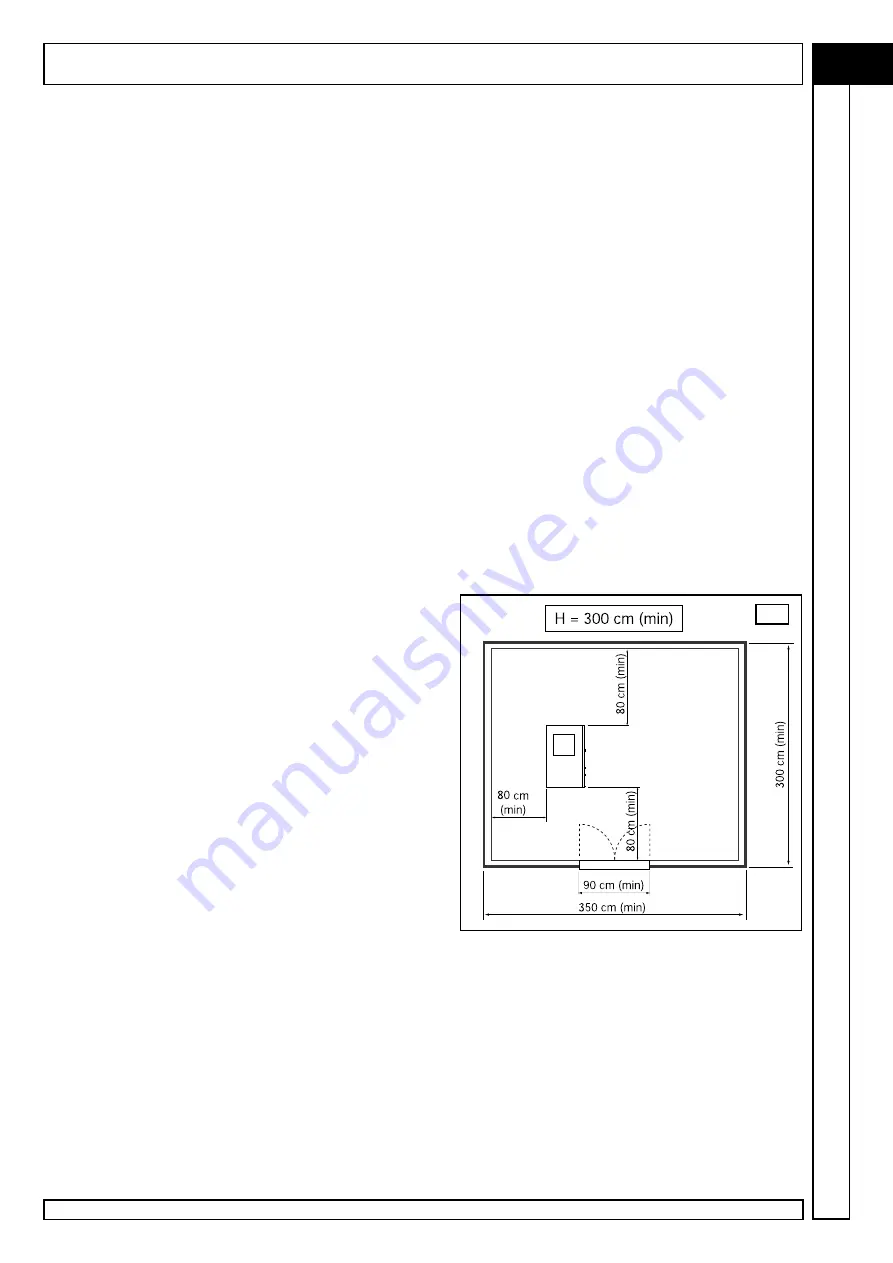

LOCATION (fig. 2)

The room chosen for the installation of the compressor should meet

the following requirements and comply with what is specified in the

current safety and accident prevention regulations:

•

low percentage

of fine dust,

•

proper room ventilation and size

that allow room

temperature under 45° C. In the event of inadequate hot air

discharge, fit the exhaust fans as high as possible.

Condensate should be collected either into a container or a tank,

or a water/oil separator should be fitted.

CONDENSATE IS A POLLUTING MIXTUrE!

It must not be let

into the sewage.

The dimensions of the spaces are indicative only but it is advisable

to follow them as closely as possible.

INSTALLATION

DESCrIPTION OF THE COMPrESSOr