Chemicar Europe NV - Baarbeek 2 - 2070 Zwijndrecht - België/Belgium

2

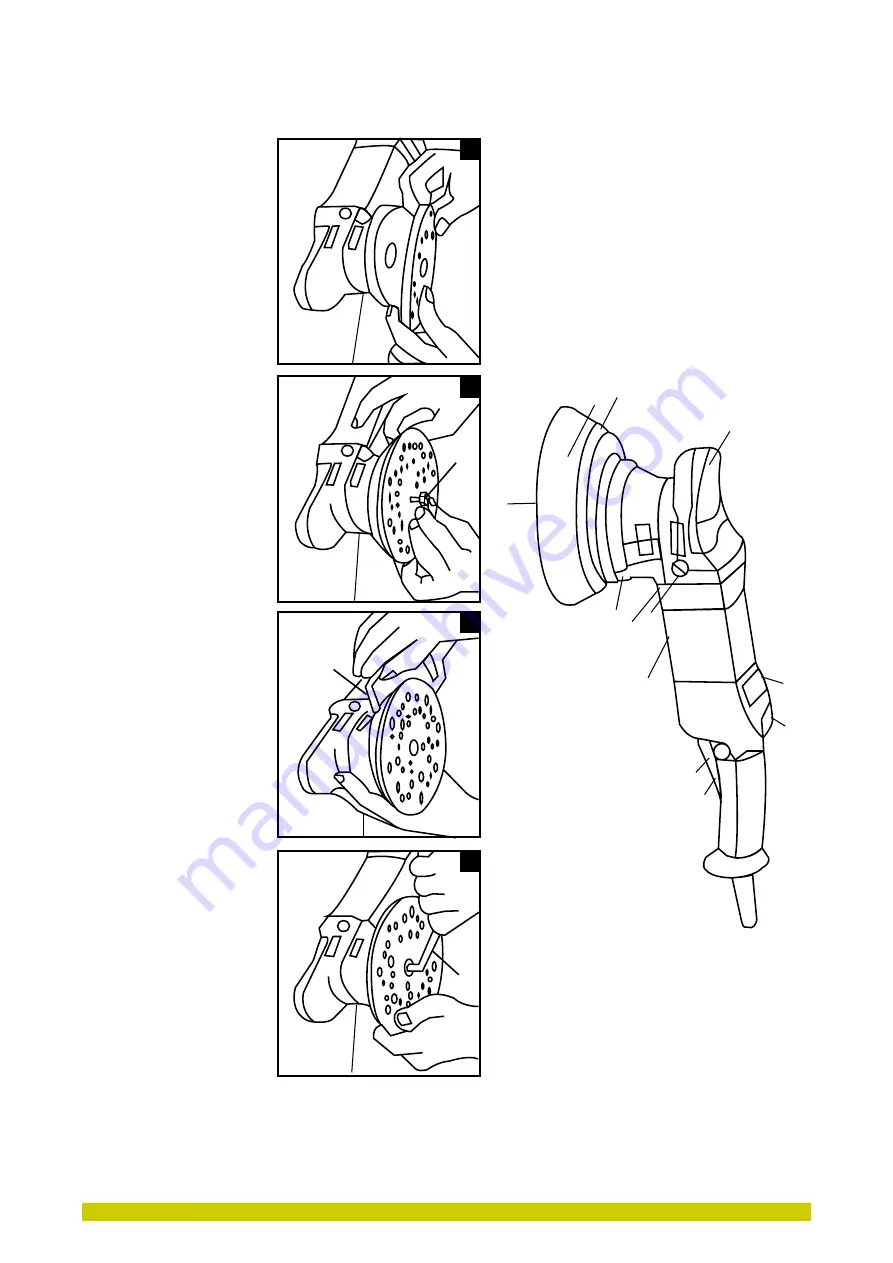

1-

Identification plate

2-

ON/OFF switch

3-

Electrical speed control

4-

Backing plate fixing screw

5-

Backing Plate Allen wrench

6-

A

uxiliary handle (not supplied)

7-

Handle

8-

Buffing pad (not supplied)

9-

Handle fixing screws

10-

Velcro faced backing plate

11-

Motor v

entilation slots

12-

A

uxiliary protection (optional)

13-

Switch locking button

11

3

2

13

1

7

10

8

4

4

5

5

5

9 6

1

2

3

4