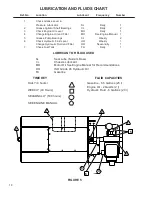

A. Lubricate the agitator shaft bearings located on the outside front and rear of the slurry-tank.

B. Service the automatic lubricator on the pump as needed (for service see page 8).

C. Check the engine oil and replenish when necessary. Change oil and filter after first 5 hours

then 100 hours thereafter. Consult the engine operator’s manual for the correct grade of oil

and the engine break-in procedure.

WEEKLY OR EVERY 40 HOURS OF OPERATING TIME:

1. Clean the air cleaner following the instructions in the engine operator’s manual.

2. Lubricate all the points on the HydroSeeder® as outlined in the daily maintenance section and, in

addition, lubricate the two grease fittings on the clutch/pump.

3. Check the level in the hydraulic oil reservoir - maintain level with dipstick on filler cap.

4. Inspect the slurry-tank for build up of residue in the suction area and clear if necessary.

SEASONAL AND WINTER STORAGE MAINTENANCE:

1. Drain the slurry tank of all water prior to storage and leave the drain plug disconnected.

2. Park unit in suitable location and chock wheels to prevent inadvertent movement.

3. If possible cover machine with tarp or park inside of an enclosure.

4. Store the HydroSeeder® with all slurry valve handles in the open position. To prevent damage from

freezing, it is advisable to remove all slurry valves and store in a heated area.

5. Pour one quart of mineral oil or environmentally safe lubricant into the pump housing and spin pump

by hand to prevent rust in the pump. Remove drain plug.

6. Chip and steel brush any interior rust spots in the slurry-tank and touch up with paint. See numbers

2 and 3 in Maintenance Section (IV) of the Safety Summary Section page 3.

7. Lubricate all fittings.

8. Lubricate equipment again just prior to starting operation after storage.

9. Change hydraulic oil and filter. (400 hours)

10. Disconnect battery cables. In cold weather, remove battery and store in safe warm place.

11. Add fuel stabilizer to fuel tank.

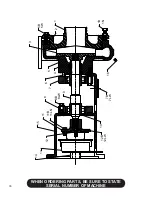

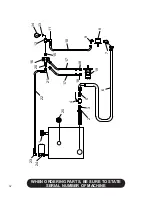

HYDRAULIC SYSTEM:

The hydraulic system on your Finn HydroSeeder® is designed to give trouble free service, when properly

maintained. The most important areas of maintenance are the hydraulic oil and filtration. The reservoir

holds 6 gallons of ISO Grade 46 Hydraulic Oil. The hydraulic oil should be replaced per the lubrication

schedule or if the oil becomes milky or it gives off a burnt odor. The hydraulic oil filter must be replaced

on schedule with a 25 absolute micron filter - Finn part #021618. The hydraulic system relief is factory set

at 2,250 psi.