SAFETY

I 42/60 GAS

Rev.000

29/01/10

11/34

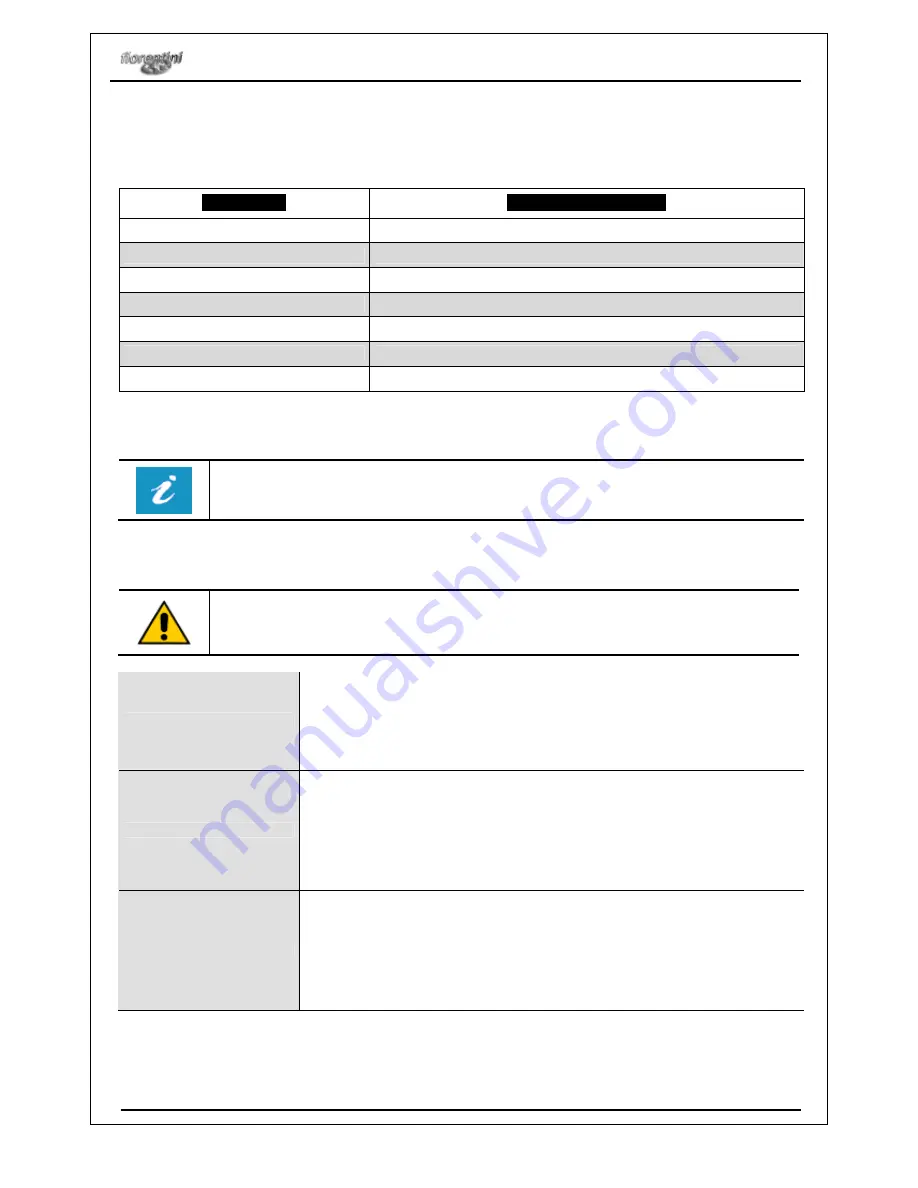

3.4. OPERATOR’S QUALIFY

The scheme below sumarizes the operator qualify requested for each kind of operation.

OPERATION

OPERATOR’S QUALIFY

Driving/control of the machine

Trained operator

Installation/ disinstallation

Fiorentini technician

Mechanical parts maintenance

Fiorentini technician

Electric parts maintenance

Fiorentini technician

Cleaning maintenance

Trained operator

Dismantling and demolition

Fiorentini technician

FIORENTINI S.r.l. suggest to train the operator before using the machine. The operator also must be trained

about safety rules and carefully read this manual.

FIORENTINI S.r.l. is not responsible for any possible damage to people and/or things caused by

the non-observance of the instructions dealt within this manual.

3.5. SAFETY AND WARNING DEVICES

•

It is absolutely forbidden to tamper or disconnect safety and warning devices while

the machine is working;

•

It is important to check periodically safety and warning devices (see § 5.1.).

Side brushes protection

I 42/60 GAS is equipped with three nylon brushes which rotate while the

machine in on duty.

La macchina I 42/60 GAS e dotata di tre spazzole, con setole in nylon che

sono in rotazione durante il normale utilizzo. The machine cannot reach

dangerous areas thanks to fixed plastic protections set up on each brush. The

brush protection can be only willingly removed.

Protection for hot parts

I 42/60 GAS is equipped with a steel rear case to protect hot parts of the

engine and the engine itself.

This case can only willingly be opened. Make sure that it is well closed.

Warning devices

I 42/60 GAS is equipped with several warning devices:

One acustic warning device like a claxon. It has to warn people who are

near the machine while its operating;

one flashing yellow light to signal the machine operating.