INSTRUCTIONS FOR STARTING AND USE THE MACHINE

I 42/60 GAS

Rev.000

29/01/10

23/34

4.7.6 SQUEEGEE ADJUSTMENT

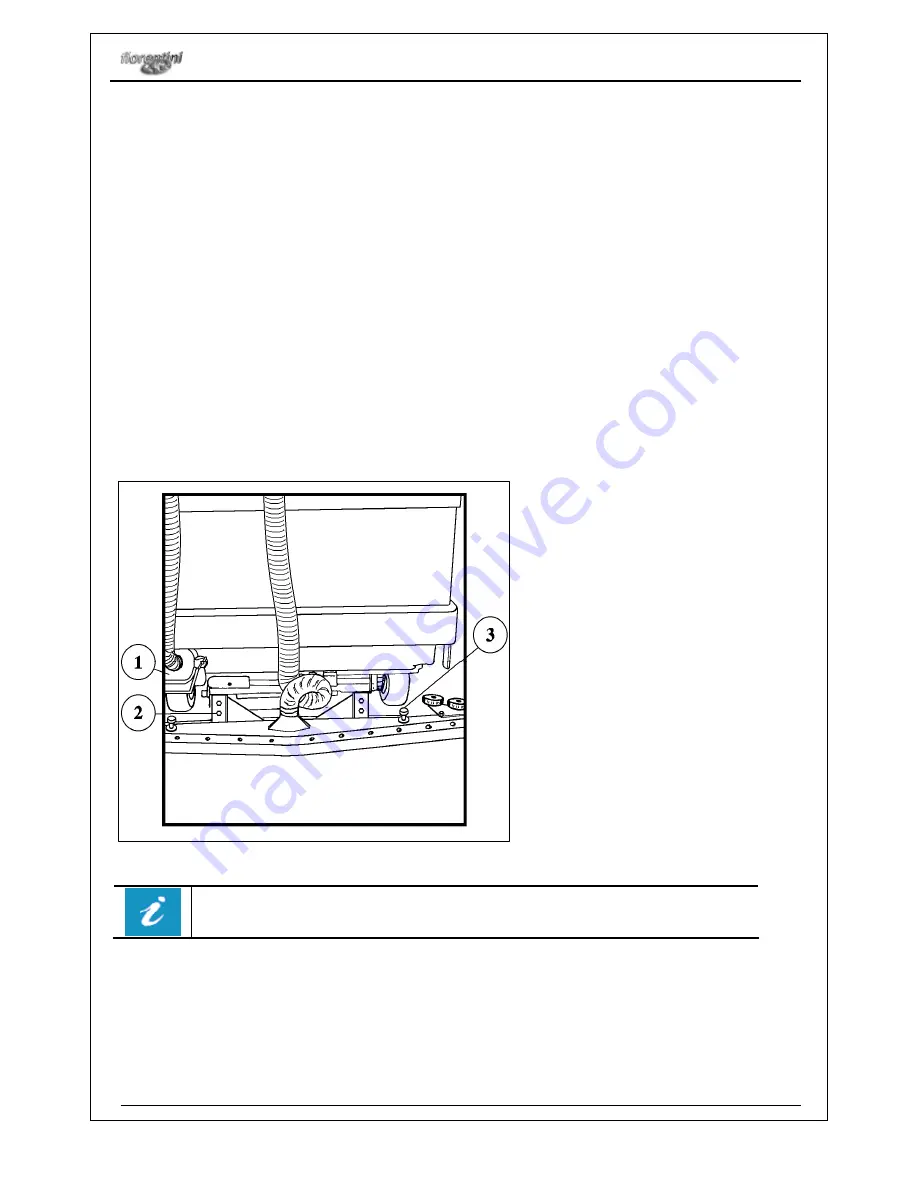

The squeegee must be perfectly adjusted to get a perfect floor drying. ICM 42 is equipped with a V-shaped

squeegee, as shown in . This type of squeegee performs very well in collecting water from the floor to the

suction hose, but is particularly sensitive to the parallelism to the floor. Therefore, adjust first its angular

position through the screws so that its rubber blades get the same slanting on the floor along its entire width.

If blades are more pressed at their ends than in their centers, unscrew the upper screws and screw the

lower ones , then tighten the lock nuts. If, on the contrary, blades are more pressed at their centers than in

their ends, perform the opposite operation. After having reached the right angular position, adjust the

pressure. Turn the ring nut and tighten it to increase pressure to the floor, or loosen to decrease it. The right

pressure is got when the edge of the rear blade touches the floor with a slanting of approx. 60°-45° r eferring

to the floor. If the pressure is too high, the rear blade will touch the floor with its side surface, and not with its

edge. If the pressure is too low, the edge doesn’t work well and lets some water on the floor, particularly on

an uneven floor. Of course the optimal adjustment is confirmed by very good results of the drying operation,

and the operator’s experience will contribute to enhance such good results. Note that often drying is

negatively affected by a wrong suction operation. If the suction hose doesn’t work well, drying will continue to

be bad, even with all adjustments attempts. In this case:

a) accurately clean the suction hoses, their inlets and filters and the squeegee itself

b) check the vacuum motors operation

c) confirm that all inspection openings of the tank are closed.

Make sure that the two wheels of the squeegee are well regulated in order to keeps both

its blades parallel to the floor.