9

FIPA Spider vacuum traverse

4. INSTALLATION AND COMMISSIONING

Ensure that the delivered vacuum traverse matches the delivery note. If any parts are missing,

please contact our Technical Team. Many problems during installation and the test run can be

avoided if this manual is read and understood thoroughly before installation. For safety reasons, it is

imperative to have detailed knowledge of the equipment. The FIPA Spider vacuum traverse is used

in conjunction with an electrical vacuum pump. This is permanently mounted. Strictly observe the

instructions for the vacuum pump.

Safety instructions for installation

>

The employee responsible for installation of the FIPA Spider vacuum traverse must ensure

that the suspension structure (e.g. the FIPA crane system or the FIPA jib crane or similar) is of

sufficient size to hold the dead weight of the vacuum traverse including maximum load plus an

adequate safety factor.

The electrical connection may only be carried out by qualified personnel in compliance with the

applicable electrical standards.

Check that the supply voltage conforms to the data stated on the motor rating plate of the vacuum pump.

The FIPA Spider vacuum traverse has a two-pole and earthing-pin plug on the rear for connecting.

The vacuum traverse can thereby be connected to the chain hoist with a spiral cable.

Please note that the vacuum traverse only needs single phase electricity!

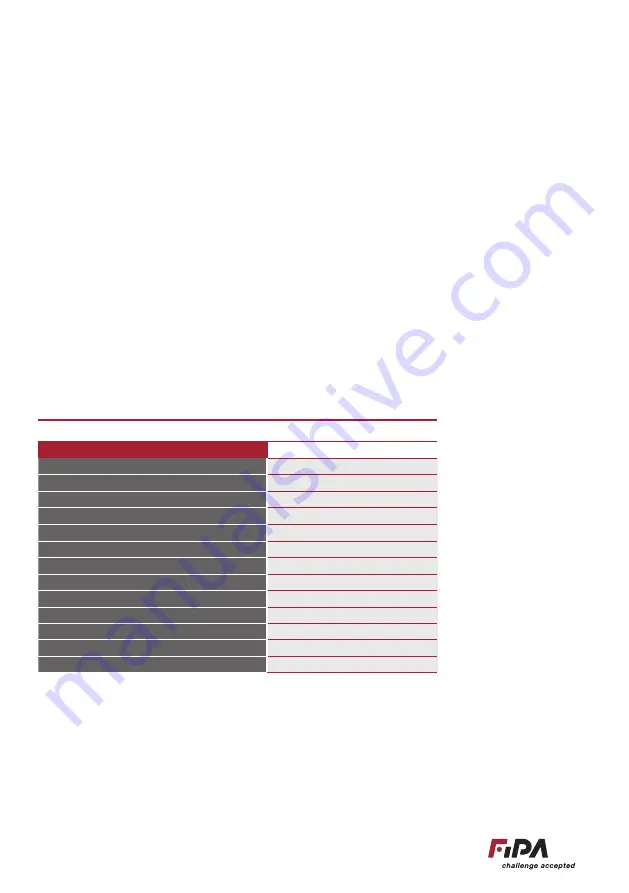

Technical data

Part No.

DT.5C-1 / 50 Hz

Suction power

[m

3

/h]

5

Final pressure (absolute)

[mbar/hPa]

120

Rated power

[kW]

0.12

Voltage supply

[V]

220 - 240

Current consumption

[A]

1

Speed

[n/min]

2800

Noise level 1m

[dB(A)]

59

Weight

[kg]

5.4

Vacuum inlet ø

[mm]

9

Operating temperature at 20°C

[°C]

65 - 70

Permissible ambient temperature

[°C]

0

-

40°

Storage and transport temperature

[°C]

-20 - 50°C

PMax. Moisture (1000m above sea level)

[%HR]

80

A three-phase variant is also available on request

The vacuum traverse must be operated in ventilated areas to ensure that it functions safely. It is

essential to prevent hot air from building up in the work area.

Do not place any objects in the vicinity of the motor cooling impeller which could obstruct the

normal air flow.