EQUIPMENT:

FIRE

CLASS

PRECEPT EN

PUBLICATION:

FIRECLASS PREC EN INST

ISSUE No. & DATE:

3 13/09/18

PAGE 15 of 30

21. Reinstallation of the chassis is the reverse of

removal. Reconnect all wires and ensure none

are trapped between the chassis and backbox.

Do not connect the field wiring at this stage.

22. Refit the door. The refitting procedure is the

reverse of removal. Ensure that the earth strap

and ribbon cable are reconnected correctly.

23. Place the left-hand battery into the bottom of the

enclosure. The terminals should be positioned

towards the centre of the enclosure and the

battery should be adjacent to the left side of the

backbox, fixed by the raised indents in the

backbox, one above the battery and one to the

right.

24. Place the right-hand battery into the bottom of

the panel. The terminals should be positioned

towards the centre of the enclosure and the

battery should be adjacent to the right side of

the backbox located by the raised indents in the

back box above the battery and to the left.

25. Connect the black battery lead to the power

supply “Batt -” [battery negative] terminal and

connect the red battery lead to the power supply

“Batt +” [battery positive] positive terminal

[situated on the motherboard for the Precept EN

2/4, 8 and 16 panels and repeater panel or on

the separate power supply board in the Precept

EN 32 panel]. The location of the motherboard

battery terminals are shown in Figure 10 &

Figure 12. Fit the connector on the end of the

black lead onto the negative (black) terminal of

the left-hand battery. Fit the connector on the

end of the red lead onto the positive (red)

terminal of the right-hand battery.

26. Connect the blue battery lead between the

positive (red) terminal of the left-hand battery

and the negative (black) terminal of the right-

hand battery. Note that the batteries will not

power the panel until the mains supply is

energised.

11.2.2 Optional C1631 Repeater Interface

Installation

Warning: Observe anti-static precautions

1. Ensure that the panel and repeaters are

powered down and the main and standby

supplies are disconnected.

2. On the fire alarm panel and each repeater,

remove the jumper link at J22 (adjacent to J9)

and fit a C1631 repeater interface to connectors

J13 and J9 located immediately to the left of the

Zone Expansion ribbon connector on the right-

hand side of the C1627 motherboard. See

Figure 10. The board should be held in place by

the 12mm high plastic spacer provided.

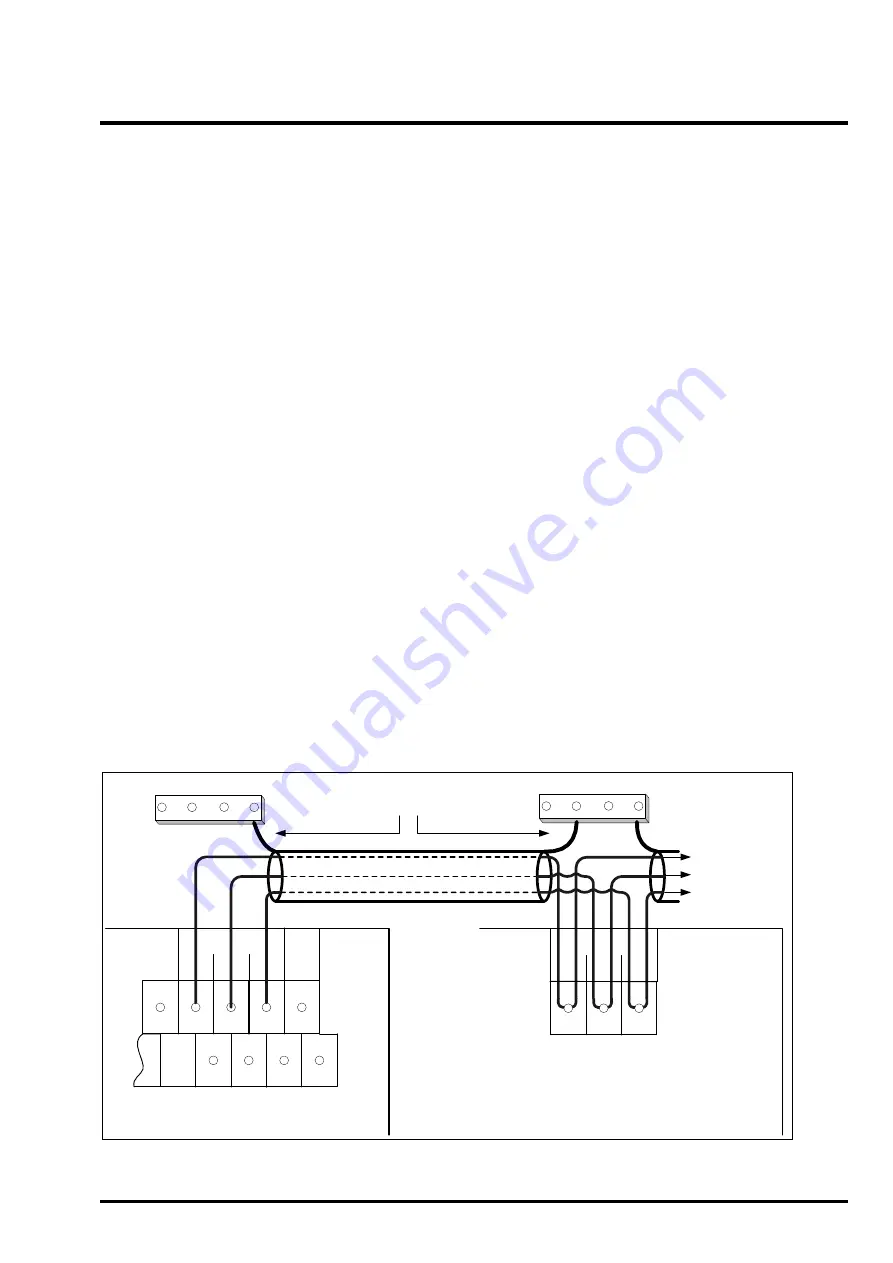

3. Connect the RS485 data cable as shown in

4. If the repeater is powered from the panel then

connect the Aux 24Vdc supply from the panel to

the repeater.

5. Connect the repeater mains power supply (if

required) to the L, N and E terminals as

described above for the panel.

Note: Use only RS485 screened data cable.

Figure 13 - Repeater connection diagram

EARTH BAR

EARTH BAR

Repeater

A

B

G

N

D

[Top right hand corner of C1627 motherboard]

Data Cable Screen

Panel

Power Supply connections not shown.

Repeater

A

B

G

N

D

Repeater [max 5 off]

[Top right hand corner of C1626 motherboard]