EQUIPMENT:

FIRE

CLASS

PRECEPT EN13

PUBLICATION:

FIRECLASS PREC EN13 INST

ISSUE No. & DATE:

2 22/07/2021

PAGE 13 of 32

10.2 Installation Instructions

1. Carefully remove the control panel from the

packing and lay the panel on a flat surface.

2. Open the door of the panel.

3. Locate the spares bag and check that the

following items are present:

Item

Precept EN13

2/4

Precept EN13

8/16

Mains Fuse

T1AH250V

20mm

1 off

T3.15AH250V

20mm

1 off

Battery Fuse

F2AL250V

20mm

1 off

F5AL250V

20mm [8/16]

EOL

capacitor/resistor

device for normal

zone monitoring

22μF

/3k9

2/4 off

22μF

/3k9

8/16 off

EOL resistors for

I.S. zones.

3k9 0.25W

2/4 off

3k9 0.25W

8/16 off

Engineer’s door

keys

Key Ref.:

801 [Flat]

1 off

Key Ref.:

801 [Flat]

1 off

Access Control

keys

Key Ref.:

801 [Tubular]

1 off

Key Ref.:

801 [Tubular]

1 off

Positive battery

lead

Red

1 off

Red

1 off

Negative battery

lead

Black

1 off

Black

1 off

Battery coupling

lead

Blue

1 off

Blue

1 off

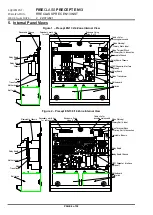

10.2.1 Panel Installation Instructions

1. Disconnect the display ribbon cable from the

motherboard header.

2. Disconnect the earth strap connecting the door

and backbox via the spade terminal on the door.

3. Unscrew the hinge pin at the bottom of the door

whilst supporting the door. Swing the bottom of

the door clear of the backbox and pull the door

away from the top hinge pin.

4. Place the door carefully to one side and replace

the bottom hinge pin in the backbox.

5. Unscrew and remove the two lower chassis

screws and

only slacken

the top two mounting

screws.

6. Carefully lift the chassis upward to align the

screw heads with the large holes in the chassis

keyholes. Lift the chassis clear of the upper

screws and rest the chassis in the bottom of the

enclosure. Take care not to strain the wires that

remain connected to the backbox.

7. Disconnect the earth strap connecting the

backbox and chassis at the earth bar.

8. Disconnect the flying leads from the transformer

to the mains terminal block and earth bar.

9. Remove the chassis from the enclosure and

place carefully to one side.

NOTE: The door and chassis both contain

PCBs with sensitive and fragile electronic

components on them. You must place them

in an area that is clean, dry and dust-free,

where they will not be damaged. You can

place them inside the original packing box

but you must ensure that sufficient soft

packing is used to keep the door and chassis

separated.

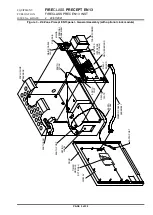

10. Identify the three indented holes in the backbox

that are used to mount the enclosure.

11. Place the enclosure in the desired location and

mark the position of the top indented hole.

Remove the enclosure and fit a suitable fixing to

the wall. Hang the enclosure from the top fixing

point and ensure that it is level. Mark the

locations of the other two mounting holes.

12. Remove the enclosure from the wall and fit

suitable fixings to the two remaining mounting

points. Fix the enclosure to the wall using all

three mounting points.

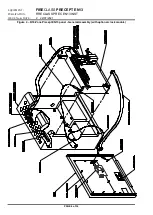

13. Carefully remove the required knock-outs in the

panel enclosure and gland all field wiring in

place ensuring that the cable conductors are of

sufficient length inside the enclosure. Ensure

that all conductors are clearly labelled.

DO NOT

remove knock-outs from any unused cable

entries. Any unused cable entries which are

open must be sealed with a suitable plug

(available separately).

14. Connect the earth drain wires of the field cabling

to the brass earth bar positioned at the top of the

backbox. Up to two drain wires may be

connected to each terminal.

15. Ensure that continuity of any cable shield is

maintained through to the last device on the

circuit. The shield must only be connected to

enclosure earth in the panel by using the earth

bars provided. [Different requirements apply for

the screen of data cable used for connecting

repeaters - see 10.2.2 below].

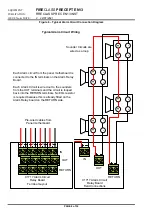

16. Connect the incoming protective earth conductor

to the Earth terminal in the mains terminal block.

This is the primary earth point and is labelled Í

[also labelled E]. See Section 0

17. Clear any dust and debris from inside the

enclosure.

18. Connect the mains-in Live cable to the mains

terminal block [L terminal] as indicated in section

19. Connect the mains-in Neutral cable to the mains

terminal block [N terminal] as indicated in

section 0

20. Secure the mains-in cable to the cable clamp

adjacent the mains terminal using the cable tie

supplied. NOTE: The clamp should be over the

outer cable insulation.

21. Reinstallation of the chassis is the reverse of

removal. Reconnect all wires and ensure none