44

Application, Installation & Commissioning Doc. version 2

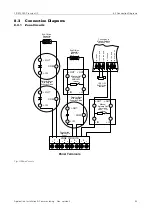

6.1 Cable Recommendations

FIRECLASS Prescient III

ELECTRICAL SAFETY:

The volt-free relay contacts provided within the panel

must not be used to directly switch any voltage that

exceeds 50 V AC or 75 V DC. (Please also refer to relay

rating data).

This equipment requires a 230 V AC supply. All installa-

tion work should be carried out in accordance with the

recommendations of BS5839 Part 1 and the current edi-

tion of the IEE regulations by suitably qualified and

trained personnel.

6.1

Cable Recommendations

All external connections (except for mains power) to the

panel must be made using shielded fire resistant cable

such as FP200. The shield of each cable must be con-

nected to the earth bar inside the enclosure. The maxi-

mum cable core size permitted is 2.5 mm

2

CSA (cross

sectional area). The total end-to-end resistance of any

core should not exceed 20 Ω.

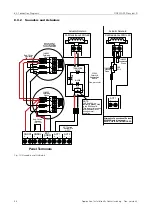

In addition, connection to the Status Lamp Units (SLUs)

should be made via data-grade fire resistant cable. The

total cable length for all SLUs should not exceed

2000 metres.

Mains cable compliant to BS6004, BS6500, or equiva-

lent must be used for connection to the Power Supply.

Cable up to 4 mm

2

CSA may be used.

6.2

Installation Procedure

1

Unpack the Control panel. If the panel door is locked

locate the panel keys (usually fixed to the top of the

panel) and open the door.

2

Locate the small plastic bag containing the installa-

tion spares as follows:

– 22 off End of Line resistoxs (10 kΩ – colour code

brown, black, orange, gold).

– Remote controls switch resistors:

– Sound alarms - 4.7 kΩ (yellow, purple, red, gold).

– Silence alarms – 1.8 kΩ brown, grey, red, gold).

– Reset – 560 Ω (green, blue, brown, gold)

– Valve monitoring resistors:

– Valve open – 2.2 kΩ (red, red, red, gold)

– Valve closed – 680 Ω (blue, grey, brown, gold)

– 3 off End of Line Capacitors (22 ºF)

– Spare 20 mm mains fuse T5AH250V

– Spare 20 mm battery fuse F6.3A250V

– 2 off cable ties

– 2 off C1565 actuator suppression units

– A set of battery leads (positive, negative and

jumper lead)

3

Disconnect the display ribbon cable from the internal

control board by pulling firmly but gently on the rib-

bon cable connector.

4

Disconnect the Earth wire from the chassis at the

top left of the chassis.

WARNING: Battery Operating

Temperature

Avoid operating temperatures

outside the range of -15 °C / 5 °F to

+50 °C / 122 °F for float/standby

applications.

The recommended normal operat-

ing temperature is 20 °C.

HIGH TEMPERATURE will reduce

battery service life. In extreme

cases this can cause Thermal Runa-

way, resulting in high oxygen/

hydrogen gas production and bat-

tery swelling. Batteries are irrecov-

erable from this condition and

should be replaced.

LOW TEMPERATURE will prolong

battery life but reduce output

capacity.

DANGER: Do NOT Incinerate Batteries

Do not incinerate batteries. If

placed in a fire, the batteries may

rupture, with the potential to

release hazardous gases and elec-

trolyte. VRLA batteries contain sub-

stances harmful to the environ-

ment.

Exhausted batteries must be recy-

cled. Return them to the battery

manufacturer or take them to your

Council waste disposal site for

appropriate disposal.

DANGER: THIS PANEL MUST BE

EARTHED

All electrically conductive parts of

this installation must be bonded to

the protective earth for safety.

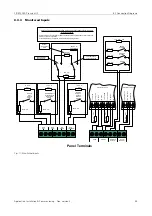

CIRCUIT

Cable Cross-

sectional Area

Maximum

Cable Run

Zone

1.0 mm

350 metres

Zone

1.5 mm

600 metres

Alarm/Actuator

1.0 mm

200 metres

Alarm/Actuator

1.5 mm

350 metres

Table 14: Cable Recommendations