F

IRE

F

LEX

®

N

2

B

LAST

®

Integrated Fire Protection System

O

WNER

'

S

O

PERATION

&

M

AINTENANCE

M

ANUAL

Page 6 of25

FM-076B-0-6A

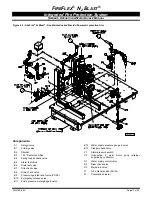

4.3 PLACING SYSTEM IN SERVICE

1. Verify that the system has been properly drained.

Main water supply control valve (

D1

) is CLOSED.

Main drain valve

(D3)

is OPEN. Emergency release

valve

(B10)

is CLOSED.

2. CLOSE main drain valve

(D3).

3. OPEN priming valve

(B1)

.

4. Air supply shall be OPENED to restore supervisory

pressure to sprinkler piping.

Note:

On systems provided with an air pressure

maintenance device (air option style "B"), verify that

the ½" by-pass valve

(E8)

in the air pressure

maintenance device trim is CLOSED and that both ¼"

valves

(E6 & E7)

are OPEN.

5. Nitrogen generator compressor will come on and the

“Operating” green light will illuminate until the N

2

storage tank pressure reaches maximum

(approximately 75 Psi) and the compressor shuts off.

6. OPEN drain test valve

(B6)

.

7. PARTIALLY OPEN main water supply control

valve

(D1)

.

8. When full flow develops from the drain test

valve

(B6)

, CLOSE the drain test valve and verify that

there is no flow from the drip check valve

(B7)

when

the plunger is pushed.

9. FULLY OPEN the main water supply control

valve

(D1)

.

10. Verify that the alarm test valve

(B5)

is CLOSED and

that all other valves are in their "normal" operating

position.

11. Depress the plunger of the drip check valve

(B7)

. No

water should flow when the plunger is pushed.

12. Check and repair all leaks.

13. When the N

2

storage tank pressure reaches

maximum (approximately 75 Psi) Nitrogen generator

compressor will come off and the “Standby” amber

light will illuminate.

14. Make sure the Nitrogen generator air pressure

maintenance device valve is open. (see figure 4.2 or

4.4)

15. Perform sequence of operation (refer to chapter 4.4).

4.4 AIR PRESSURE SETTINGS

- Preaction compressor start @ 20 Psi

- Preaction compressor stop @ 35 Psi

- Preaction low air pressure switch is set at 25 Psi

- Nitrogen generator storage tank is filled @ 75 Psi

- Nitrogen generator air pressure maintenance device

is set @ 35 Psi

Note

: all pressure setting has a 5% tolerance