REV. A Page 4

Fire Ring Burners

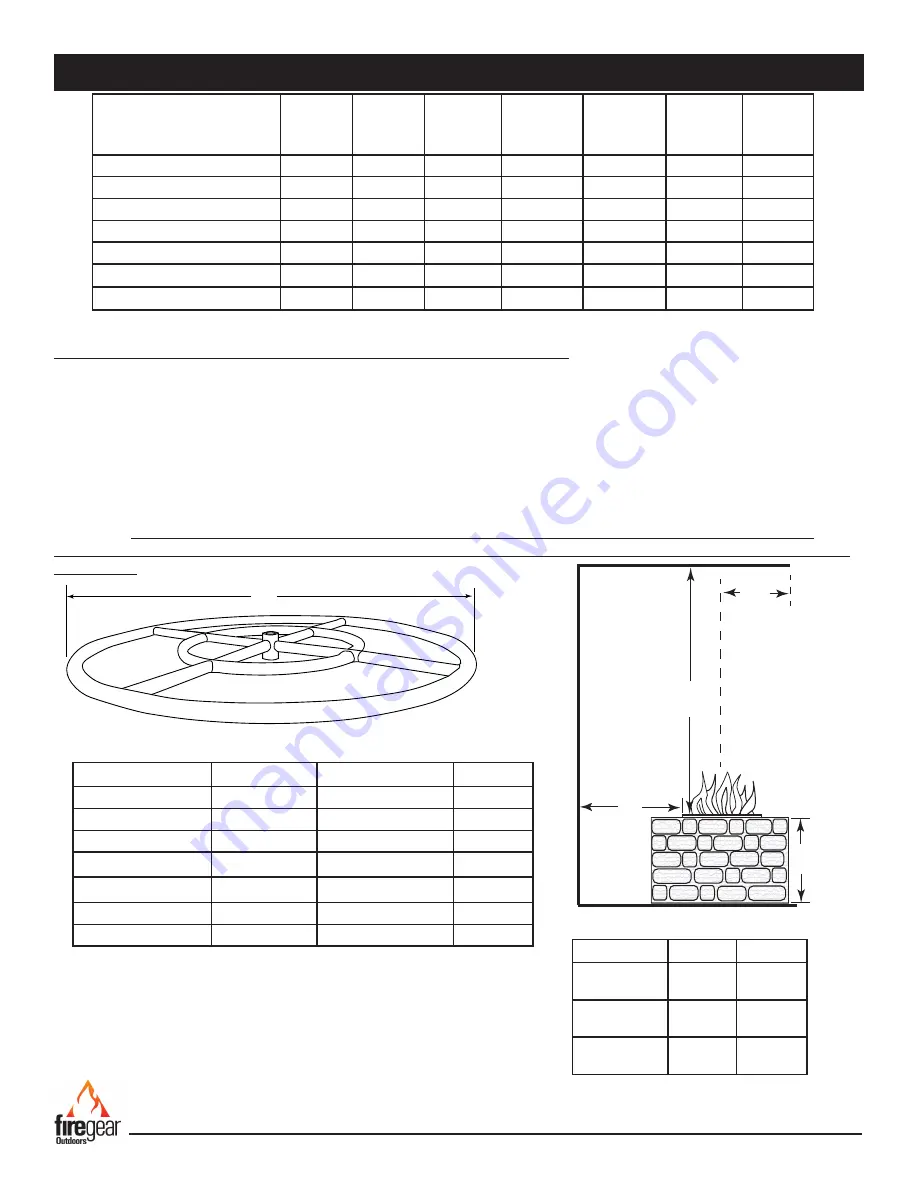

FIRE RING SPECIFICATIONS

Table 1

Suggested pan sizes and clearance specifications

Fig. 1

Fire Ring Dimensions; refer to Table 1.

Model:

Orifice NG

Natural Gas

Btu’s Orifice LP

FG-FR-6SSK

OAS-NG34

50,000

(14.65kW)

OAS-LP47

FG-FR-12SSK

OAS-NG34

50,000

(14.65kW)

OAS-LP47

FG-FR-18SSK

OAS-NG29

75,000

(21.9kW)

OAS-LP41

FG-FR-24SSK

OAS-NG22

100,000 (29.31kW)

OAS-LP35

FG-FR-30SSK

OAS-NG25/64” 250,000 (73.26kW)

OAS-LP12

FG-FR-36SSK

OAS-NG25/64” 250,000 (73.26kW)

OAS-LP12

FG-FR-48SSK

OAS-NG25/64” 250,000 (73.26kW)

OAS-LP12

Table 2

Btu Specifications

Table 3

Gas Pressures

Models

Fire Ring Kit

Center

Hub

Size

Pan/Disc

Depth

A

Fire Ring

Diameter

Min. Inside

Pan

Dimension

B

Combustible

Side Wall

C

Combustible

Ceiling

D

Combustible

Floor

FG-FR-6SSK

½”

2 ½” - 3”

6”

10”

36”

96”

18”

FG-FR-12SSK

½”

2 ½” - 3”

12”

16”

36”

96”

18”

FG-FR-18SSK

½”

2 ½” - 3”

18”

22”

36”

96”

18”

FG-FR-24SSK

½”

2 ½” - 3”

24”

28”

36”

96”

18”

FG-FR-30SSK

¾”

2 ½” - 3”

30”

34”

36”

96”

18”

FG-FR-36SSK

¾”

2 ½” - 3”

36”

40”

36”

96”

18”

FG-FR-48SSK

¾”

2 ½” - 3”

48”

52”

36”

96”

18”

Disclaimer:

Btu listings are based on 7.0”WC for Natural Gas and 11.0”WC

for Liquid Propane (LP) at the burner orifice. Flex line size and proper gas

pipe sizing will also affect Btu’s. As a result your Btu’s may vary slightly from

Table 2 specifications.

BEFORE INSTALLING A FIRE RING DETERMINE PAN SIZE TO BE USED:

Fire Ring Kits listed above are not provided with a burner pan for installation. We suggest you provide an appropriate

non-combustible burner pan to install the Fire Ring. Suggested burner pans sizes in Table 1 are strictly recommended

based on the Fire Ring model size. The pans can be round, square, flat disc or solid flat surface.

NOTE:

It is

recommended to use 304 Stainless Steel. Burner pans should have ¼” drainage holes to prevent standing water in pan

and the center hole for burner connection should be 1-inch diameter for kits FG-FR-6SSK, FG-FR-12SSK, FG-FR-18SSK,

and FG-FR-24SSK. The FG-FR-30SSK, FG-FR-36SSK, and FG-FR-48SSK models require a 1¼” center hole.

A recommended material thickness for any burner pan or disc is 16 gage. Once a burner pan has been determined then

proceed with this manual to complete the installation.

CAUTION: DO NOT use stiff screen/perforated metal as a burner pan. Some gases are heavier than air and

screen/perforated metal can allow gas to flow downward in an enclosure which could cause delayed ignition or

explosions.

A

C

B

D

CL

24”

Max

Overhang

(Center Line)

Fig. 2

Clearance to combustibles

Pressure

NG

LP

Min. Inlet

5.0” WC

(1.24kPa)

10.5” WC

(2.61kPa)

Max. Inlet

10.5” WC

(2.61kPa)

13.0” WC

(3.23kPa)

Normal Inlet

7.0” WC

(1.74kPa)

11.0” WC

(2.73kPa)