REV. 10-24-12 Page 9

CAUTION

: Children and adults should be alerted to the hazards on high surface temperatures and should stay away to

avoid burns or clothing ignition. Young children should be carefully supervised when they are in the area of the appliance.

WARNING:

Do not use this appliance if any part has been under water. Immediately call a qualified service technician

to inspect the appliance and to replace any part of control system and any gas control, which has been under water.

OPERATION

SAFETY WARNINGS

1. Never leave the Fire Pit unattended during operation.

2. Clothing or other flammable materials should not be placed on or near the appliance.

3. Any guard or other protective device removed for servicing the appliance must be replaced prior to operating the

appliance.

4. Installation and repair should be done by a qualified service person. The appliance should be inspected before

use and at least annually by a qualified service person. More frequent cleaning may be required as necessary. It

is imperative the control compartment, burners and circulating air passageways of the appliance be kept clean.

5. Inspect the fuel supply connection before each use of the appliance.

6. Temporary storage of this appliance indoors is permissible only if it has been disconnected from its fuel supply

(Natural or L.P. gas line).

WARNING

1. This appliance is hot when operated and can cause sever burns if contacted.

2. Do not burn any solid fuels in this appliance.

READ ALL LIGHTING INSTRUCTIONS BEFORE ATTEMPTING TO LIGHT FIRE PIT

CAUTION

: Ensure you have leak tested the fire pit before operating.

1. Insert key into gas valve.

2. Push and hold the red button on the manual Piezo ignitor and ensure sparking is

occurring at the probes inside the fire pit.

3. Rotate the key counter-clockwise in gas valve to allow gas to flow.

4. Gas should ignite within 10 seconds or less. If fire pit does not light within

10 seconds turn key clockwise to turn OFF the gas supply. Check igiitor probe

loc ation (Fig. 8), ensure there is an 1/8” gap between the probes with a good stong

spark then repeat steps 2 through 4.

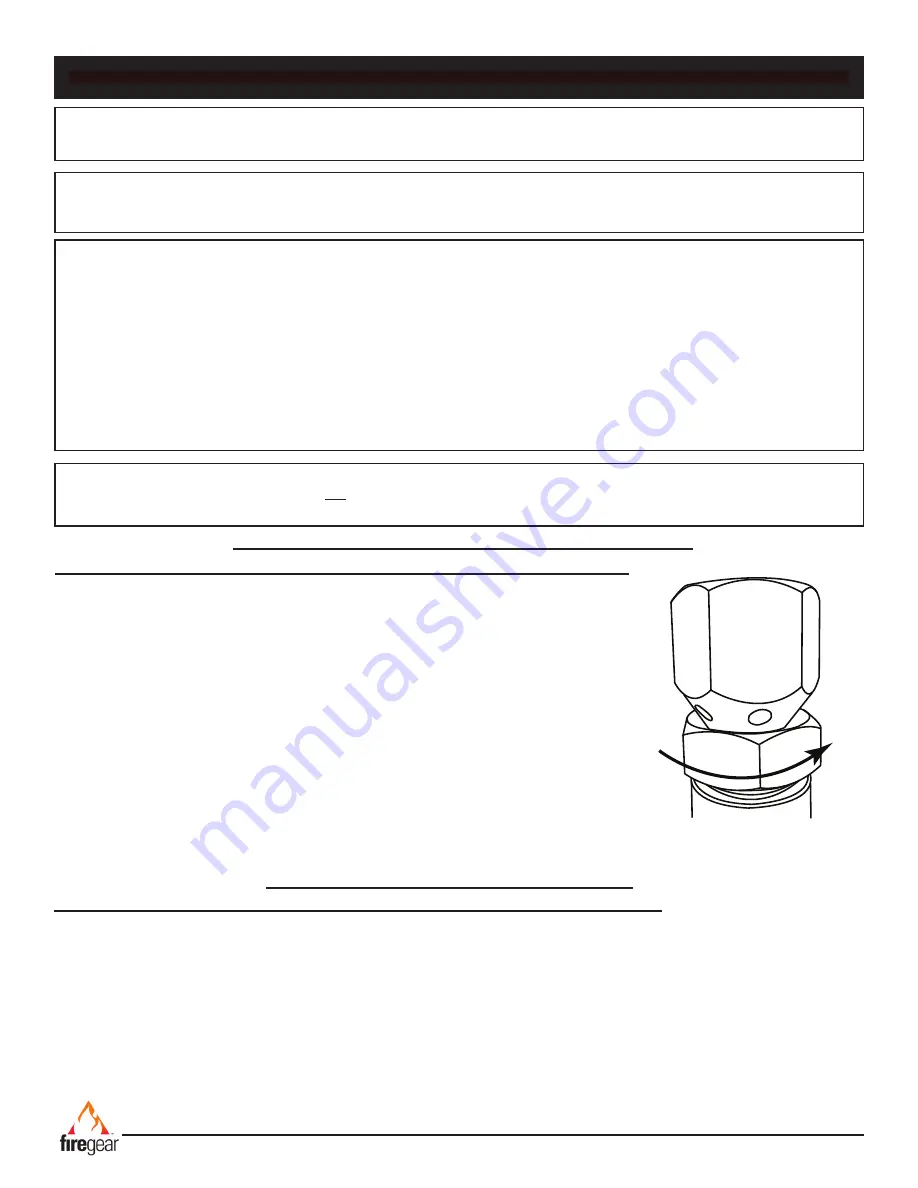

Once fire pits lights flame color adjustment can be made turning the air shutter nut

under the burner pan. It is recommended that the nut be OPENED until the gas/air

mixture makes a rushing sound (like a blow torch); then slowly CLOSE until the rushing

sound diminishes. A desirable flame is bright yellow with little or no brown at the tips.

Too yellow flame can create excessive sooting (See fig. 10).

To Close

Fig. 10

Air shutter adjustment

MANUAL SPARK IGNITION LIGHTING INSTRUCTIONS

MATCH THROW LIGHTING INSTRUCTIONS

READ ALL LIGHTING INSTRUCTIONS BEFORE ATTEMPTING TO LIGHT THE FIRE PIT

CAUTION

: Ensure you have leak tested the fire pit before operating.

1. Insert key into gas valve.

2. Light a long match or butane lighter and hold it near the burner.

3. Rotate the key counter-clockwise in gas valve to allow gas to flow and simultaneously apply the burning match as

close to burner as possible to light the fire pit.

4. Gas should ignite within 10 seconds or less. If fire pit does not light within

10 seconds turn key clockwise to turn OFF the gas supply. Ensure there is not too much media on top of firestar that

my inhibit gas flow and try again.

Matchlight Fire Pits