OPERATING SEQUENCE

FPB with standard battery Box Power

Start -

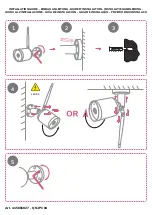

Ensure that the four (4) AA batteries are fully charged, and not used before hand.

•

Ensure all connectors to the module are secure.

•

Ensure gas is flowing to the FPB.

•

With the transmitter, push the ON button and wait for the sparking in the burner.

•

Gas value will open and a flame will appear in the burner.

•

If these steps are completed, the burner is working properly.

•

TROUBLE SHOOTING THE FIREGEAR FIRE PIT NOWL SYSTEM 19’’, 25’’ DIRECT SPARK IGNITION

The Firegear Fire Pit Bowl System is controlled by a module inside the value box under the burner. The control module (AF-5000 MOD)

has built-in error detection for common operating fault conditions. When the module detects an error, it will emit a series of beeps. The

beeping pattern will help to determine the cause of the operating fault.

TROUBLESHOOTING

Fault Codes

The AF-5000MOD control module has built-in error detection for several common operating fault conditions. When the control module

detects an error, it will emit a series of beeps. The beeping pattern will help to determine the cause of the operating fault.

Ignition Safety (Protection for Ignition system):

Error Code: One beep every one second.

Description of Fault: Warn users if the pilot is not successfully

ignited in 15 seconds.

How to Clear: Press OFF then ON buttons to re-attempt ignition.

What to Check:

Ensure gas supply is turned on.

•

Ensure that the gas line is purged of air. Air is common in the gas line if the appliance has just been installed, has been discon-

•

nected then re-connected to the gas line, or if the appliance has been unused for an extended period of time.

Ensure there is no blockage in the gas line.

•

Make sure that the flame sensor electrode is clean. Soot buildup will insulate the electrode and will not allow for proper flame

•

sensing.

Ensure orange/white leads from module are plugged into the “PILOT” connection on the valve body.

•

Ensure green/white leads from module are plugged into the “MAIN” connection on the valve body.

•

Verify lead from igniter on electrode assembly is connected to the “I” terminal on the module.

•

Verify lead from flame sensor on electrode assembly is connected to the “S” terminal on the module.

•

Verify that the black ground lead from the module is connected to a proper ground on the appliance.

•

REV 9/8/09 Page 8

Sensor Safety (Protection for Flame sensor):

Error Code: 4 Beeps every one second (Constant beeping)

Description of Fault: Warn users that the flame sensor detects a flame already present when ignition sequence is initiated. This fault

will also occur if the flame sensor is shorted to ground.

How to Clear: Press OFF then ON buttons to re-attempt normal ignition.

What to Check:

Check if flame is actually present when valve is turned OFF (valve replacement necessary if yes).

•

Ensure that the flame sensor electrode is not touching the burner or another metal surface.

•

Check if the flame sensor wiring is worn, frayed, or otherwise damaged.

•

Replace electrode assembly.

•

Replace module.

•

Thermal Safety (Overheat Protection):

Error Code: 4 Beeps every 2 seconds.

Description of Fault: Warn users that the modules internal temperature has exceeded 170 deg. F.

How to Clear: Module’s internal temperature must cool to below 160 deg. F and then press ON button.