REV. 6-25-19 Page 27

Square Flat Disc Fire Pits

SECTION C THERMOCOUPLE FLAME SENSE (TFS) INST

ALLA

TION

Thermal Safety (Overheat Protection):

Error Code

: 4 Beeps every 2 seconds.

Description of Fault

: Warn users that the modules internal temperature exceeds 170°F.

How to Clear

: Module’s internal temperature must cool to below 160°F and then press ON button.

What to Check

:

1.

Ensure that there is proper ventilation to the control module.

2.

Is module located in unapproved location, too close to burner?

3.

Move to cooler location.

Wireless Remote Transmitter Will Not Operate Appliance

1.

Make sure that the transmitter is within the 25-foot operational range of the control module.

2.

Ensure batteries in transmitter are fully charged and properly installed.

3.

If using the battery pack, ensure batteries are fully charged and properly installed. Also, make sure the battery

pack’s 4-pin connector is securely connected to the battery pack and control module.

4.

If using optional AC adapter, ensure that the AC adapter leads are securely attached to “POWER” connection on

the control module. Also, ensure that the AC adapter is connected to a live 120VAC power source.

5.

Ensure “Remote/Off” switch on control module is set to “Remote”.

6.

Ensure the control module has learned the transmitter’s security code (learning section page 23).

7.

Make sure that the remote transmitter is not placed/mounted to a metal surface, which will reduce the operating

range.

8.

Make sure that there is not a large metal obstruction between the remote transmitter and the control module.

Igniter Electrode Sparks Frequently During Operation

1.

The control module will generate a spark at the igniter electrode if the system is in the ON position, but does not

sense a flame.

2.

Make sure that the flame sensor electrode is clean. Soot buildup will insulate the electrode and will not allow for

proper flame sensing.

3.

Make sure that wind does not blow the flame off of the flame sensor. The sensor hood and the appliance media

(rocks, glass, etc.) provides shielding from the wind. Ensure that the sensor hood and appliance media is properly

positioned per the appliance instructions. If wind is too strong, and the flame will not maintain contact with the

flame sensor, the appliance should not be operated.

Flame Modulation Will Not Work or Works Backwards

1.

Ensure that the black and red leads from the battery pack are securely connected to the red and black leads from

the Hi/Lo latching solenoid located on the valve body (red to red and black to black).

2.

Verify that the selector switch on the battery pack is set to LATCHING SOLENOID only.

3.

Check functionality with all transmitters to determine if there is an issue with the main control system or an

individual transmitter. If the issue is with an individual transmitter, make sure that the batteries in both the transmit

ter and battery pack are installed properly and fully charged.

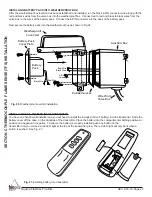

OUT

PILOT ADJ

IN

MAIN

PILOT

Battery

Pack

Black (Ground)

Orange

Green

White

2-Brown

White

Black (-)

Red (+)

Black (4-Pin Connector)

Red

Red

Black

Black

Lear

n A

UX

Remot

e/OFF

AF-5000MOD-1

Module

I

S

Ignitor

Sensor

Thermocouple Ground Wire

Fig. 34

Wiring Diagram