12

OD42 Outdoor Gas Fireplace

INSTALLATION

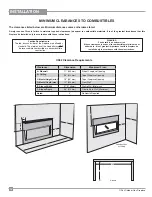

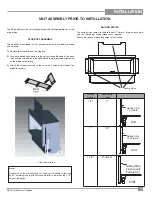

Due to the extreme heat this fi replace emits, the mantel

clearances are critical.

Combustible mantel clearances from

top of front facing are shown in the diagram on the right.

Note:

Ensure the paint that is used on the mantel and the

facing is "heat resistant" or the paint may discolour.

Combustible Material

2

0

12

6

4

8

10

12" (305mm)

Standoff

Metal Stud

(On Edge)

0

14

Non-combustible

Facing

To Unit

Base

1" (25mm)

26-1/2”

18”

23”

10

20

26

Top of

Fireplace

Opening

11”

MANTEL CLEARANCES

NON-COMBUSTIBLE REQUIREMENTS

2-7/8”

( 3mm)

6-9/16”

(167mm)

10-7/8”

(276mm)

16”

(406mm)

38-1/16” (767mm)

Non-combustible

Material

Non-combustible Material

Non-combustible

Material

7

43-11/16” (1110mm)

Summary of Contents for OD42-N

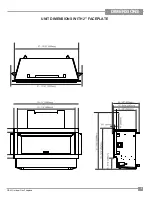

Page 5: ...OD42 Outdoor Gas Fireplace 5 DIMENSIONS UNIT DIMENSIONS WITH 2 FACEPLATE ...

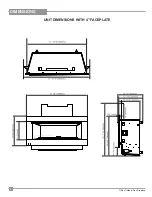

Page 6: ...6 OD42 Outdoor Gas Fireplace DIMENSIONS UNIT DIMENSIONS WITH 4 FACEPLATE ...

Page 36: ...36 OD42 Outdoor Gas Fireplace NOTES ...

Page 37: ...OD42 Outdoor Gas Fireplace 37 NOTES ...