Connection to Power Source

High voltage danger from power source!

Consult a qualified electri-

cian for proper installation of receptacle at the power source.

This welder must be grounded while in use to protect the operator from electrical shock. If you are not sure if your

outlet is properly grounded, have it checked by a qualified electrician.

DONOT

cut off the grounding prong or alter

the plug in any way.

DONOT

use any adapters between the welder’s power cord and the power source receptacle.

Make sure the POWER switch is OFF. Connect the welder’s power cord to a

properly grounded 120 VAC, 60 Hz, single-phase, 20 amp power source.

DO NOT

operate

this welder if the source voltage is less than 110 Volts AC or greater than 132 Volts AC.

Contact a qualified electrician if this problem exists. Improper performance and/or damage to

the welder will result if operated on inadequate or excessive power.

Extension Cords

For optimum welder performance, an extension cord should not be used unless absolutely necessary. If neces-

sary, care must be taken in selecting an extension cord appropriate for use with your specific welder.

Select a properly grounded extension cord that will mate directly with the ac power source receptacle and the

welder power cord without the use of adapters. Make certain that the extension is properly wired and in good

electrical condition (minimum gauge size 10/3 AWG, maximum 25 ft. length).

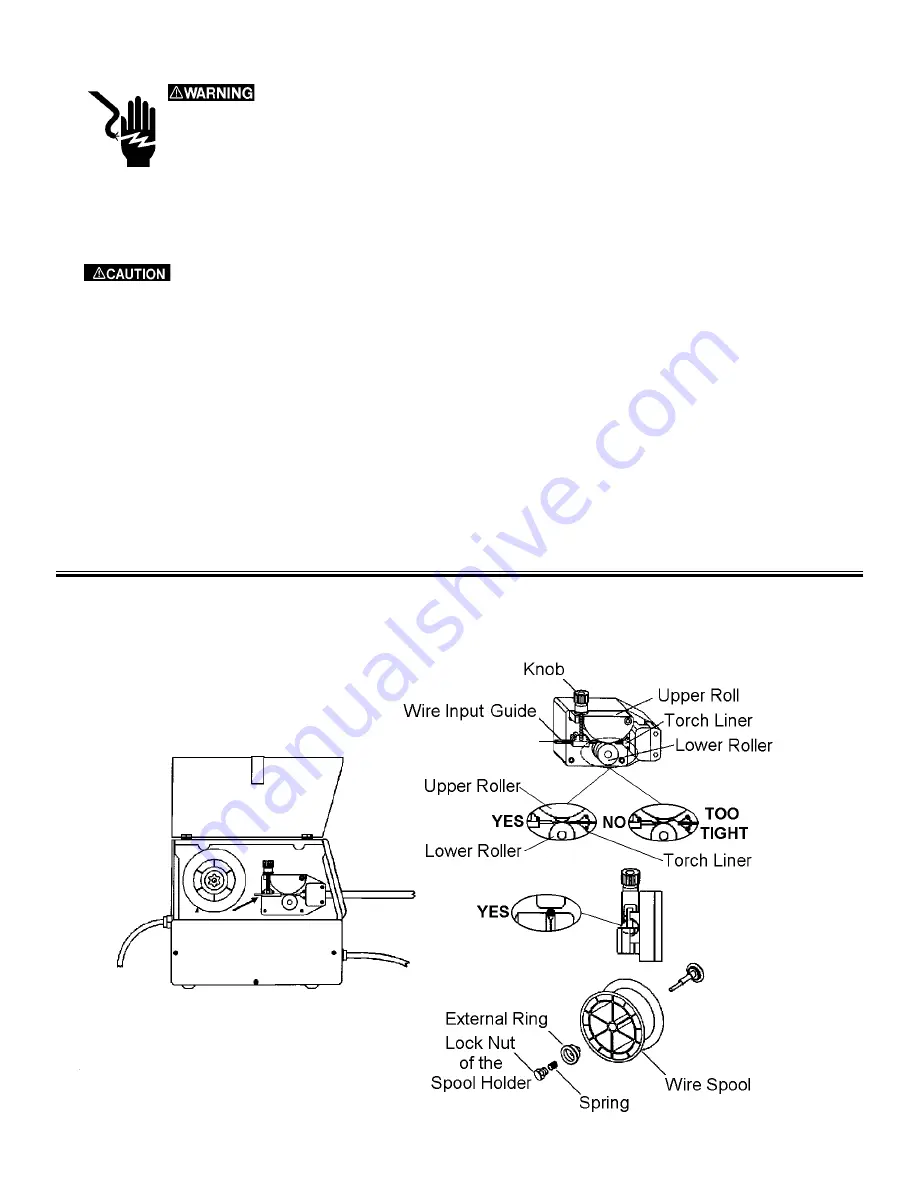

INSTALLATION OF THE WELDING WIRE

The power source is supplied with a spool of .035” Spool Flux MIG Wire. Install the wire into the feeding sys-

tem by following the instructions below and referring to Figure 2. MIG (GMAW) welding applications require

argon shielding gas.

7

Figure 2: Wire Installation

Summary of Contents for FP-90

Page 2: ......

Page 27: ...23 Figure 21 FP 90...

Page 29: ...25 Figure 22 FP 90 Wiring Diagram...

Page 30: ...26...