2. Aluminum is often anodized to prevent oxidation. However, an anodized surface will NOT conduct electric-

ity. Therefore, to weld anodized aluminum, you MUST sand or grind the anodized coating from the weld

joint area and from the site where the workpiece clamp will be connected.

Determine whether or not the aluminum you intend to weld is

anodized. Touch the two probes of an electrical continuity tester or

ohmmeter to the aluminum in question. Set the probes an inch or two

apart. If there is no indication of electrical continuity, the aluminum

is anodized.

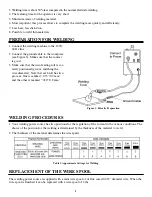

If the base metal pieces to be joined are thick or heavy, it may be

necessary to bevel the edges (with a metal grinder) at the point of

contact as shown in Figure 6. The angle of the bevel should be

approximately 60º.

ALWAYS

wear safety goggles to help prevent eye injuries when grind-

ing metal. Also, inspect the grinder and verify that it is in good working condition.

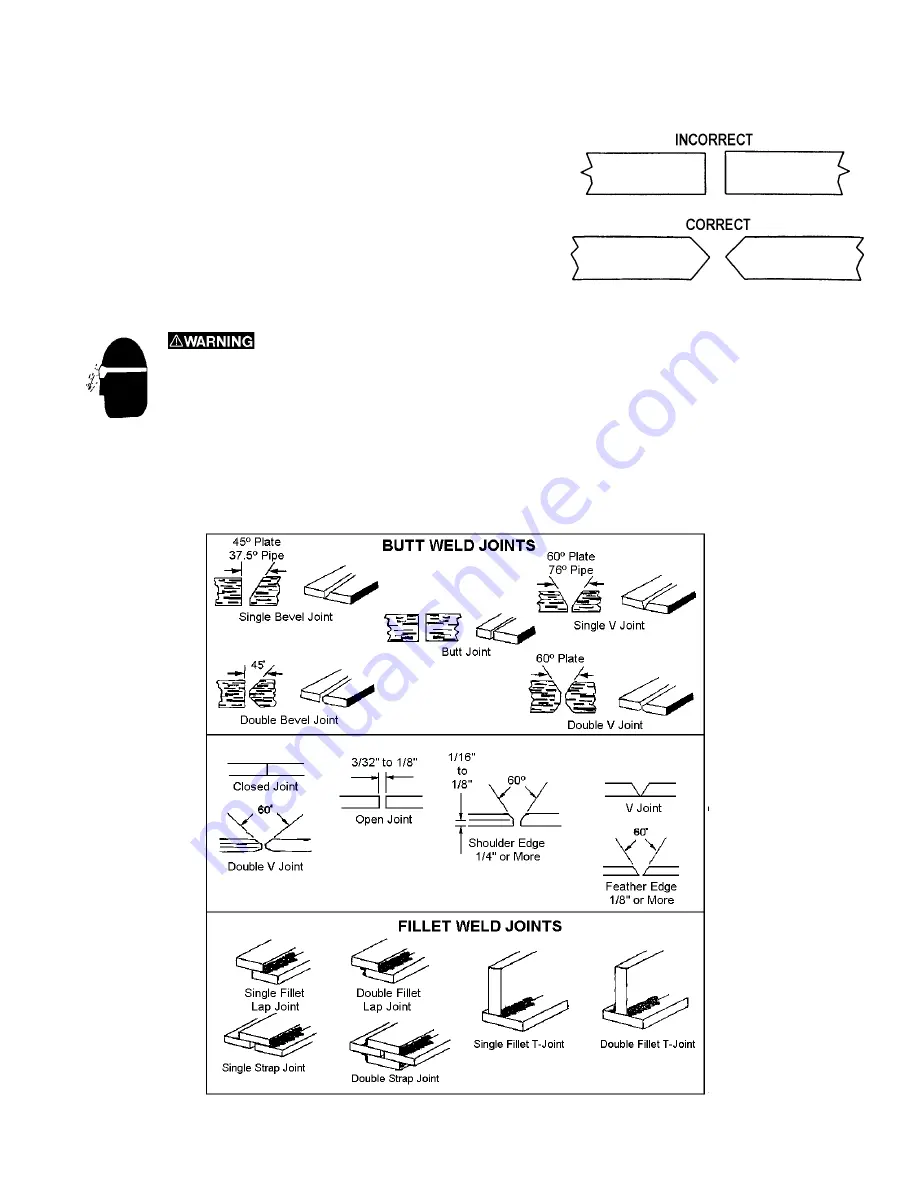

See the chart, Types of Weld Joints, in Figure 7, for detailed instructions for preparing the weld joint.

During welding, the workpieces become hot and expand. The expansion may cause the pieces to shift posi-

tions. If possible, clamp the workpieces into the position they are to occupy when the welding is completed.

13

Figure 6: Workpiece Preparation

Figure 7: Types of Weld Joints

Summary of Contents for FP-90

Page 2: ......

Page 27: ...23 Figure 21 FP 90...

Page 29: ...25 Figure 22 FP 90 Wiring Diagram...

Page 30: ...26...