WORKPIECE CLAMP CONNECTION

Connect the workpiece clamp directly to the work piece as close to the weld as possible. If it is impractical to

connect the workpiece clamp directly to the workpiece, connect it to the metal that is securely attached to the

workpiece, but not electrically insulated from it. Also, make sure the attached metal piece is of about the same

or greater thickness as the workpiece.

There is risk of electronic component damage if the workpiece clamp is connect-

ed to an automobile or other equipment with on-board computer systems, solid state electron-

ic controls, solid state sound systems, etc.

DO NOT

weld until disconnecting the cable from

the battery that is attached to chassis ground. Failure to do so may result in electronic com-

ponent damage.

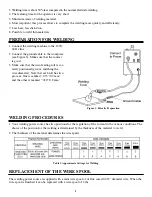

TUNING IN THE WIRE SPEED

Tuning the wire speed is one of the most important parts of welder operation. Selecting the best wire speed

setting is much the same as tuning in a radio station. It must be done BEFORE starting each welding job or

whenever changing the heat setting, wire diameter or wire type. Tune the wire speed according to the follow-

ing steps.

1. Set up and ground a scrap piece of the same type of metal that you will be welding. It should be equal to or

greater than the thickness of the actual workpiece. It should be free of paint, oil, rust, etc.

2. Select a heat or voltage setting.

3. Hold the gun in one hand allowing the nozzle to rest on the edge of the workpiece farthest away from you

and at an angle similar to that which will be used when actually welding.

ARC RAYS CAN INJURE EYES AND BURN SKIN!

Reduce the risk of injury

from arc rays.

NEVER

strike a welding arc until you and all bystanders in the welding

area have a welding helmet or shield in place and are wearing the recommended protec-

tive clothing.

DO NOT

continue unless you read, understand and intend to follow the

entire

SAFETY SUMMARY

provided at the front of this manual.

4. With your free hand, turn the wire speed control to maximum. Continue to hold onto the adjustment knob.

5. Lower your welding helmet. Pull the trigger on the gun to start an arc.

6. Drag the gun toward you while turning down the wire speed control.

7.

LISTEN!

As you decrease the wire speed, the sound that the arc makes changes from a sputtering sound to

a smooth, high-pitched buzzing sound. It sputters again if you decrease the wire speed too far.

8. Continue decreasing the wire speed until the arc noise passes the high-pitched buzzing (preferred sound)

and begins sputtering again.

9. Turn the wire speed control back, in the opposite direction, until you come back to the high-pitched arc

noise.

The wire speed is now tuned in.

REMEMBER!

Repeat this tune-in procedure whenever you select a new heat

setting, a different wire diameter or a different type of wire.

Self-shielding flux-core wire has a very wide preferred sounding range. The range

can span as much as 60 degrees on the wire speed control. It is important to know that the

heat of the arc and the penetration into the base metal increases as the wire speed increases

within the preferred sounding range for a given heat setting. Therefore, use the wire speed

control to slightly increase or decrease heat and penetration by selecting higher or lower wire

speed settings WITHIN the preferred sounding range for a given heat setting.

14

Summary of Contents for FP-90

Page 2: ......

Page 27: ...23 Figure 21 FP 90...

Page 29: ...25 Figure 22 FP 90 Wiring Diagram...

Page 30: ...26...