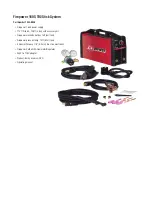

Firepower 160S TIG/Stick System

Part Number 1442-0036

• Firepower 160S power supply

• 17V TIG torch, 12.5ft (3.8m) with accessory kit

• Firepower electrode holder, 13ft (4m) lead

• Firepower ground clamp, 10ft (3.1m) lead

• 4 General Purpose 1/8” (3.2mm) dia. stick electrodes

• Firepower CutSkill 2G Flowmeter/Regulator

• 230V to 115V adapter

• Product family overview DVD

• Operating manual