TROUBLESHOOTING

FIREPOWER 160 S

Manual 0-5371

6-7

Troubleshooting

6. Measurement of In Rush Resistor R1.

Set multimeter to Ohm mode. Ohm reading should be 4Ω±5%.

Positive Probe

Negative Probe

Measure Point 17

Measure Point 18

If reading is not 4ohms within ±5%, replace Resistor R1.

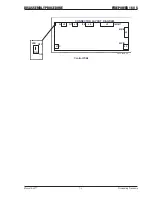

7. Power Switch S1 Continuity Check

1

Art # A-09854_AB

!

Read and follow safety information in Section 6.02 before proceeding.

1. ON/OFF switch

Place ON/OFF switch in ON position. Measure the two top terminals for continuity. Then check the two

bottom terminals for same result. If either test is faulty, replace ON/OFF switch.

Summary of Contents for TIG 160S

Page 6: ...This Page Intentionally Blank ...

Page 18: ...FIREPOWER 160 S INTRODUCTION Introduction 2 2 Manual 0 5371 Notes ...

Page 30: ...FIREPOWER 160 S SAFETY AND INSTALLATION Safety and Installation 3 12 Manual 0 5371 Notes ...

Page 40: ...FIREPOWER 160 S THEORY OF OPERATION Theory of Operation 5 2 Manual 0 5371 Notes ...

Page 54: ...FIREPOWER 160 S TROUBLESHOOTING Troubleshooting 6 14 Manual 0 5371 Notes ...

Page 59: ...DISASSEMBLY PROCEDURE FIREPOWER 160 S Manual 0 5371 7 5 Disassembly Procedure 4 Art A 09866 ...

Page 66: ...FIREPOWER 160 S DISASSEMBLY PROCEDURE Disassembly Procedur 7 12 Manual 0 5371 Notes ...

Page 69: ...ASSEMBLY PROCEDURES FIREPOWER 160 S Manual 0 5371 8 3 Assembly Procedures 8 Art A 09883 ...

Page 74: ...FIREPOWER 160 S ASSEMBLY PROCEDURES Assembly Procedures 8 8 Manual 0 5371 Notes ...

Page 78: ...FIREPOWER 160 S REPLACEMENT PARTS Replacement Parts 9 4 Manual 0 5371 Notes ...

Page 80: ...FIREPOWER 160 S ACCESSORIES Accessories 10 2 Manual 0 5371 Notes ...

Page 83: ......