SYSTEM COMPONENTS

Wire Harness

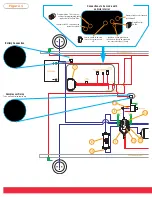

All necessary electrical wires and connectors have been included with this kit. Review Figure 1 before beginning

installation. You will have to put the major components in a position so that the wire harness will reach all of them.

Route the wire harness loosely throughout the vehicle as indicated in Figure 1. Each end of the wire harness is

marked with the major component that it will connect with.

Route the wire harness loosely throughout the vehicle as indicated in Figure 1, with the spine of the wire harness

installed on the right side of the vehicle.

Compressor Relay

Select a location in the engine compartment to mount the compressor relay. This should be a protected location

to prevent damage from flying rocks, water or debris. The compressor relay is located on the wire harness,

simply pull the compressor relay off the wire harness for mounting. Ensure that a clear access to the electrical

connection on the compressor relay is maintained. Then plug the wire harness marked “relay” back into the

compressor relay connector.

Electronic Control Unit (ECU)

The main electronic unit needs to be mounted in the interior of the vehicle, preferably under the dashboard. The wire

harness was designed to provide enough length so the ECU could be mounted under the dashboard and the harness

ran through the firewall to corresponding corners, valve block and power connections.

Valve Block

The valve block should be placed in a protected location to prevent damage from flying rocks or debris. Ensure that a

clear access to all of the fittings on the valve block is maintained. The valve block should be mounted with solenoids

pointing up or sideways, never pointing down. In order to ease installation, abbreviations for the correct plumbing

connections are scribed into the valve block.

The valve block abbreviated connector notations are:

OD = outflow from dryer

LF = left/front air spring

PS = pressure sensor

EX = exhaust

RF = right/front air spring

ID = inflow to dryer

LR = left/rear air spring

Comp Inlet = compressor inlet

RR = right/rear air spring

2

10-32 x 1-3/4” Socket Head

Cap Screw (2)

Silencer

(1)

Pressure

Sensor (1)

1/4” NPT Straight

Fittings (8)

TIPS

1. Do not run the wire harness near vehi-

cle exhaust system.

2. Secure harness firmly to vehicle with

the provided tie wraps.

3. Make sure wire harness does not inter-

fere with any moving parts of the vehicle.

4. Start with the ECU connectors and

then begin running the harness into the

interior of the vehicle.

5. Many vehicles have a blank hole in the

firewall to run wires through.

6. A grommet has been provided if a 1”

hole must be cut to get the wire harness

to the interior. Before drilling the holes,

make sure all electrical, brake and fuel

lines are cleared from the path of the drill.

Summary of Contents for 4-corner

Page 1: ......

Page 19: ...TECHNICAL 15...