SYSTEM COMPONENTS

(cont.)

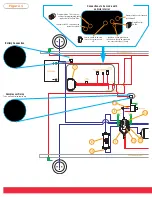

Height Sensors

The height sensor connections must go to their corresponding corners for proper sensor operation.

THE HEIGHT

SENSORS AND THE WIRE HARNESS CONNECTIONS ARE LOCATION AND POSITION SENSITIVE

. The sensor

connectors are laid out so they work with the sensors mounted on the outside of the frame rail, with the arms pointed

toward the rear of the vehicle. If the height sensors are mounted inside of the frame rail, the arms must point toward

the front of the vehicle. The system

WILL NOT

work if the height sensors are mounted incorrectly or if the wire

harness connector is in the wrong corner.

Compressor

Select a convenient location for mounting the compressor. This location should provide ample air flow and be

protected from most airborne debris. The surface should be rigid to support the unit. Some examples might include

under the hood on a fender well, or in a vented storage compartment.

Using the compressor feet as a template, mark the three 3/16” holes. Remove the compressor and drill the three

3/16” holes. Before drilling the holes make sure all electrical, brake and fuel lines are cleared from the path of the

drill. It is recommended that burrs be removed from the holes so as not to damage the rubber isolator. Mount the

compressor using the 10-32 machine screws, 10-32 nylon lock nuts and 3/16” flat washers located in your hardware

pack. Proper mounting of this compressor will provide maximum isolation. DO NOT OVER TIGHTEN, further

tightening will crush the insert and isolator and reduce vibration isolation. Secure the ring terminal to a grounded

component of the vehicle’s chassis. Find the red wire on your wire harness marked air compressor. Connect the

wiring harness to the female spade terminal on the compressor.

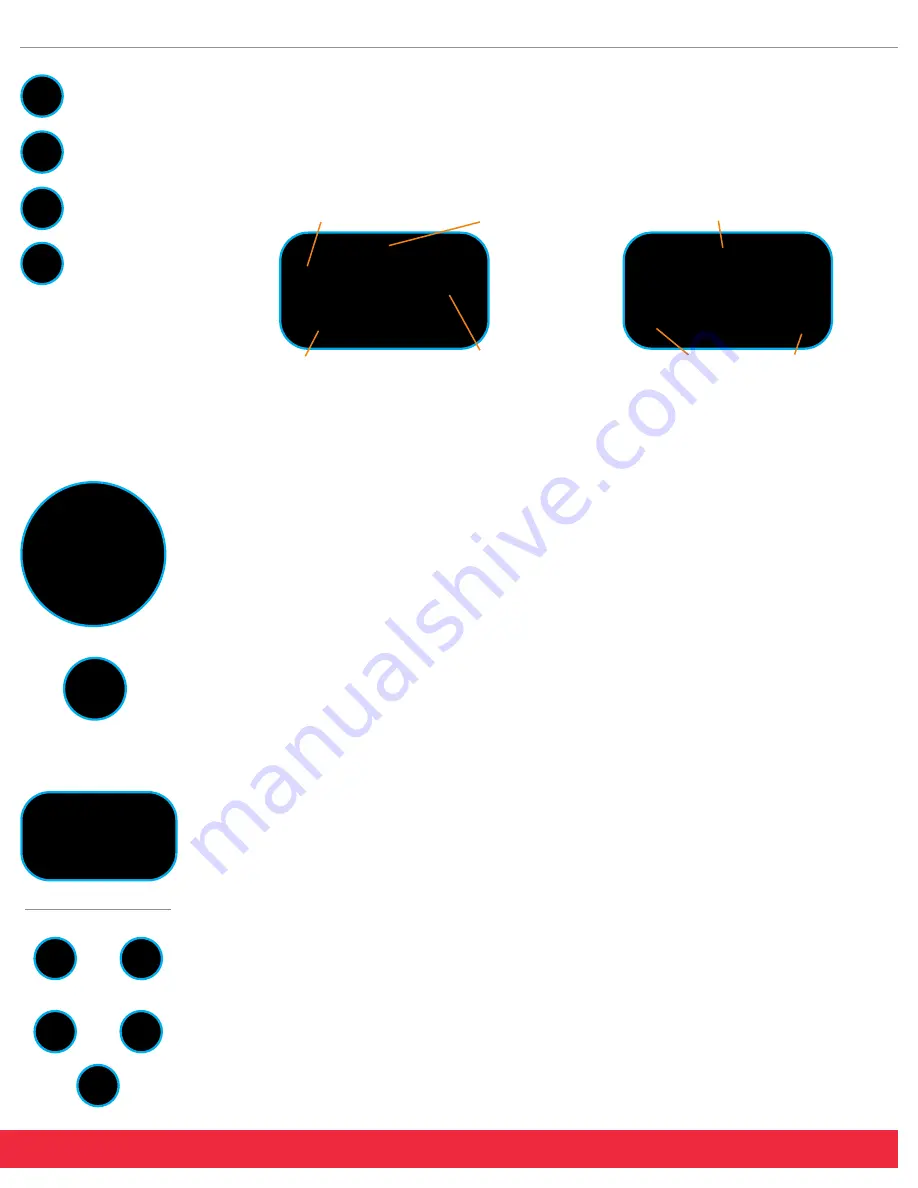

3-Gallon Air Tank

Select a location to mount the air tank. This should be a protected location to prevent damage from flying rocks or

debris. Using the holes in the tank brackets as a template, mark the locations of the mounting holes on the mounting

surface. Use a center punch to mark the center of the holes on the mounting surface.

Before drilling the holes make

sure all electrical, brake and fuel lines are cleared from the path of the drill

. Drill four 3/8” holes on the center

marks. Using the supplied 3/8”-16 x 1” hex bolts and 3/8”-16 nuts and 3/8” washers, attach the air tank to the vehi-

cle. Ensure that a clear access to the fittings on the air tank is maintained.

3

Shown with mounts

and air filter.

1/8 NPT Fitting (1)

3/8”-16 x 1 Hex

Head Bolt (4)

3/8”-16 Flat

Washer (4)

3/8”-16 Flange

Lock Nut (4)

1/4 NPT

Fitting (1)

1/4 NPT

Plug (1)

Air Tank Mounting Hardware

M5 Nylon Lock

Nut (8)

M5 x 8mm

Machine Screw (8)

M6 Nylon Lock

Nut (4)

M6 X 16mm

Machine Screw (4)

Axle Mounting Bracket (4)

Hose Clamp (4)

Height Control Linkage (8)

Height Control Arm (4)

Height Sensor Template (4)

Height Sensor Bracket (4)

Height Sensor (4)

Summary of Contents for 4-corner

Page 1: ......

Page 19: ...TECHNICAL 15...