5

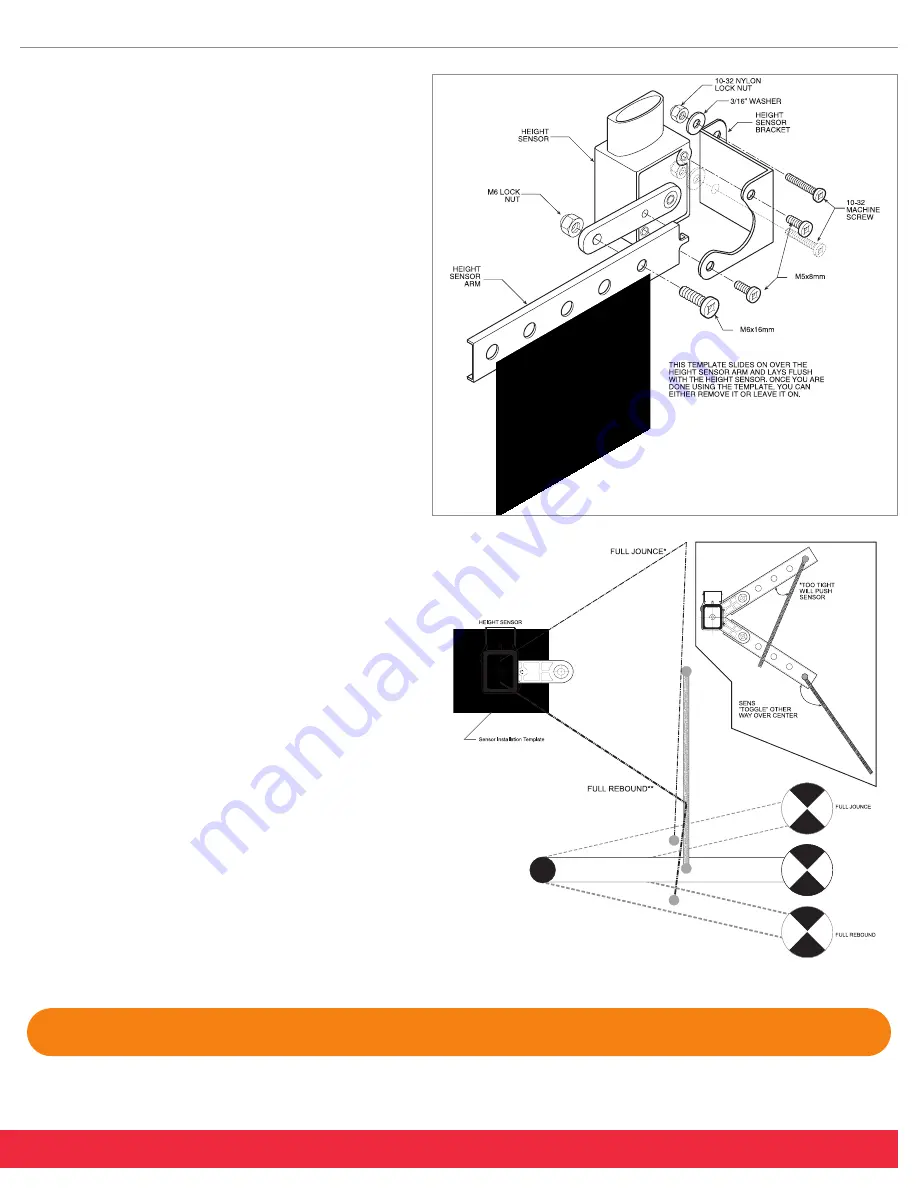

HEIGHT SENSOR INSTALLATION

Step 1

There will be a bag in your kit with all of the hardware that you will

need to put the height sensors on your vehicle. Group a height

sensor from the kit with a height sensor bracket and two M5 x

8mm machine screws as indicated in Figure 2. Attach the bracket

and height sensor template to the sensor using the machine

screws, as shown in Figure 2. Next group a sensor arm and one

M6 x 16mm and one M6 lock nut. Attach the metal arm to the

sensor arm with the M6 x 16mm and the M6 lock nut, refer to

Figure 2. Repeat this procedure for the three other sensors.

Step 2

In the process of installing the height sensors the vehicle suspen-

sion must be able to go though the entire suspension movement,

with damper attached, from full jounce to full rebound to mechani-

cally prove height sensor position, refer to Figure 3. This can be

done by either using jack method or the air spring method.

Jack Method

Raise the vehicle using a lift or platform jack rated for your vehicle

weight. Do not use wood or concrete blocks to support the weight

of the vehicle. Lower the vehicle frame onto jack stands rated for

your vehicle’s weight making sure the suspension is fully extended

to damper limit. Then to determine the jounce suspension position

that you will need to mount the height sensors, just jack the sus-

pension up to that point into the jounce stop. Make sure that the

air line is removed and that there is no air in the air springs when

using this method.

Air Spring Method

Cut four sections of air line tubing 3” in length and insert into

each air spring. Install the four inflation valves

(included with sys-

tem) in the end of each hose. Now you can inflate and deflate the

air springs on suspension to find the location to mount the height

sensors. This will also make calibration easier.

Step 3

Avoid direct heat from the engine and exhaust pipe when installing

height sensors. The height sensor linkage to the suspension

should be as close to 90° from sensor arm at ride height as possi-

ble. The sensor arm and sensor linkage should not be inline

throughout the entire travel of the height sensor linkage, from full

jounce to full rebound. An incorrectly mounted height sensor will

result in system not functioning.

The height sensor must be

mounted with the electrical connection pointing up

and the arm

in the correct position on the sensor.

Note:

The best description of a poorly mounted height sensor is shown in Figure 3. Too big of an angle between the height

sensor arm and link may allow the arm to “toggle” over center.

Figure 2

Summary of Contents for 4-corner

Page 1: ......

Page 19: ...TECHNICAL 15...