2

®

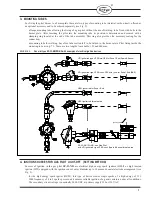

O 38 mm

120 mm

A

FLANGED MOUNTING TUBE

MOUNTING TUBE FOR WELDING

3 x O 7 mm

O 52 mm

O 64 mm

120°

6 mm

~ 25 mm

2. OPERATION PRINCIPLE AND TECHNICAL SPECIFICATION

Unit construction provides a stable flame, ignition repeatability. No moving parts ensure long, trouble-free operation

with low maintenance costs.

SureFire II™

Pilot

SP-32-

NG/PG-

ND

can operate as an intermittent (light-off), or as a continuous gas pilot.

Main parts of

SP-32-ND

pilot are: air tube (pos. 4 on Fig. 1) with combustion-cooling air inlets covered by sliding

adjusting sleeve (pos. 5) secured by locking thumb screw and gas part assembly including gas head (pos. 3) with gas

inlet (1/2” BSP) and igniter rod hole (1/2”BSP) with igniter rod holding gland (pos. 7) together with the fixed gas

tube (pos. 2). The orifice-stabilizer assembly (pos. 1) is fixed at the end of gas tube. Orifice-stabilizer assembly

consists of nipple with main and bleeding orifices, mounting bracket and stabilizer. Gas part assembly is mounted in

the air tube by means of the thread joint with mounting ring (pos. 6).

Note that gas supply line should be equipped with an effective strainer unit to prevent the orifices from clogging.

In many applications

SP-32

pilots are mounted on the main burner in the mounting tube (see p. 3).

The source of ignition is an electrical high energy spark igniter (HESI) or high tension arc igniter (HTI) for safe or

hazardous area (depending on the application) equipped with the ignition rods of outer diameter up to 16 mm and

co-axial electrode arrangement.

The ignition rod is mounted in the gas head and goes through air tube to the mounting bracket of orifice-stabilizer

assembly. The rod tip end should be placed as on drawing Fig. 1 (depending on the kind of ignition device), to

provide a successful ignition of air-gas mixture.

Gas pilot

SP-32-NG/PG-ND

can be supplied together with electrical ignition device selected depending on the

application. Ignition device is not in gas pilot scope of supply, and should be ordered separately.

SP-32-NG/PG-ND

gas pilot principle of use: gas is supplied through the inlet 1/2 " BSP to the gas head and to the

gas tube and orifice-stabilizer assembly. Gas exits the main orifice to the primary combustion zone. At the same

time a small amount of gas leaves the bleed orifice before the stabilizer plate passing into the zone where it mixes

with air to form a combustible mixture. Air flow is adjusted by the sleeve which is fixed by a thumb screw.

Orifice-stabilizer assembly is optimized for Natural gas or Propane gas/LPG. In case of other Fuel gas type or other

capacity needed contact Fireye as this may need the pilot construction changes - see p. 11 for Special Pilots.

Ignition is initiated by a spark or an electric arc generated at the tip of the igniter rod before stabilizer. The pilot

flame stabilizes at stabilizer plate with holes while the main flame stabilizes in the primary combustion zone, at the

outlet of the air tube.

Thanks to this principle of design, the pilot combustion zone is protected, the main combustion zone is outside the

igniter, and hence the air tube does not overheat and there is no need for retraction of the ignition rod.

Pilot has to be mounted on main burner such that no part of pilot shall be in the main burner flame and cannot

project beyond the heater lining or a burner throat. The distance of the tip of pilot air tube from the main burner

flame should not be smaller than 150 mm – see Appendix 2.

The flame length is

0.3 - 0.5 m depending

on the kind of gas

, gas pressure versus the pressure in combustion

chamber and environmental conditions outside boiler/heater.

In addition,

using Fireye high tension igniter type

HTSS

in the

Spark & Sense

version

, the center electrode of

igniter rod is also an ionization rod extended into the primary combustion zone and specially designed to work with

SureFire II™

Pilots

.

The HT igniter initially creates the electric arc to ignite the gas, and then the circuit switches the operating mode for

ionization detection, confirming the presence of the igniter flame

FIGURE 2.

Pilot mounting tubes: for welding and flanged