© 2021 Carrier

7

8.

PILOT START-UP, OPERATIONAL TESTS

Before proceeding with the start-up and operational tests of SP-32-NG/PG-FD pilot check the following:

8.1 Gas and air installations are correctly mounted, tight and functionally checked, including: valves, flaps,

strainers, fittings and joints (flanged and screwed), control and interlock devices.

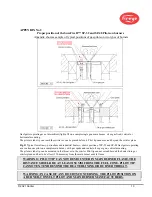

8.2 Gas and air connections to the pilot are made in accordance with the above instructions and the assembly

drawing.

8.3 Electrical components and circuits are properly connected, grounded and tested.

8.4 Power supply to the electrical circuit of the ignition device and spark or arc release should be allowed only

after assembly of the device, and when installed in the operating position on the burner or outside the burner

only to validate the operation strictly according to the device instructions e.g. on special test stand.

Then perform next steps:

8.5 Select one pilot as a representative for tests.

8.6 Prepare the burner control system to enable manual trials in a safe way.

8.7 Install for the trial period appropriate gauge and manual valve on the igniter gas supply line. This will allow

for fine adjustment of the gas pressure.

8.8 After verification of ignition device mounting and wiring, the electric igniter can be powered up. Check for

the spark or arc presence.

8.9 At presence of a spark or an electric arc from ignition device, slowly open the pilot manual shut-off gas valve

without opening the air manual shut-off valve (it should be closed).

At a certain degree of opening the pilot flame should establish.

8.10 Adjust the gas pressure slowly up to the working pressure. Pilot flame may be yellow and bushy due to too

little combustion air.

8.11 Slowly open the air valve manually until the flame stabilizes at the end of the air tube and is a blue-yellow

color. If the airflow is too low the end of the air tube may start to glow (it starts to glow at 400-500

°C) as the

main flame burns inside the igniter. Further opening of the air valve should stabilize the flame outside the air

tube. This will stop the overheating of the air tube. Flame should be as stable as possible.

Remarks:

a)

Pilot flame should be blue near the igniter tip and yellow at its end. With some kind of gases the

flame color may stay yellow.

b)

In some applications e.g. on up-fired burners, when the draught of the furnace is significant, it may

be necessary to limit the amount of air by obscuring air inlets accordingly in order to keep stable pilot

flame, bearing in mind, that air adjustment possibility of natural draught pilot is limited.

c)

A gas pilot, after correct adjustments, should ignite reliably and burn with a stable flame at each

selected gas pressure point throughout his operational pressure range. However, it should be noted

that, the pilot is not intended to be used as a burner - its turn-down ratio is typically 1:1.

8.12 In case of insufficient pilot capacity, the amount of gas and air can be further adjusted bearing in mind the

above principles.

8.13 In multiple burner and pilot applications on one heater/boiler with a similar gas and air supply installation

and similar layout on the main burner, set the other pilot’s gas and air valves to be in the same position. 8.14

Then carry out light-off tests. In case of differences in the quality of combustion adjust manual valves so that

the flame is similar to that on the test pilot. In some cases the main burner air should be adjusted.

8.15 Repeat the light-off tests several times on each pilot to confirm the repeatability of ignition. Flame should be

stable, in proper position and of desired shape.

If the

SP-32-NG/PG-FD

gas pilot has been correctly commissioned and the settings were optimized, with correct

maintenance, the igniter will operate trouble free.

REMARK

: AT THE DESIGN STAGE DETERMINE LENGTH OF CABLES AND FLEXIBLE

AIR AND GAS CONNECTIONS TO ACCOMMODATE ANY EXPECTED HEATER OR

BOILER CONSTRUCTION MOVEMENT