M

ODEL

400-CE R

ESTAURANT

R

ANGES

I

NSTALLATION

I

NSTALLATION

NOTICE

These installation procedures must be followed by qualified personnel or warranty will be void.

ENFORCEMENT: THE REQULATIONS WILL BE ENFORCED:

THIS APPLIANCE MUST BE INSTALLED IN ACCORDANCE WITH THE REGULATIONS IN FORCE WITHIN

THE COUNTRY OF DESTINATION. THIS APPLIANCE IS FOR PROFESSIONAL USE AND MUST ONLY BE

USED BY TRAINED PERSONNEL.

THE INSTALLATION MUST CONFORM WITH THE NATIONAL BRITISH STANDARDS, THE GAS APPLIANCES

(SAFETY) REGULATIONS 1992 (S. I. 1992/1629, AND THE GAS APPLIANCES DIRECTIVE (DIRECTIVE

90/396/EEC).

1. The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in excess of 3.5 kPa.

2. The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping system at test pressures equal to or less than 3.5 kPa.

Southbend reserves the right to change specifications and product design without notice. Such revisions do not

entitle the buyer to corresponding changes, additions, or replacements for previously purchased equipment.

This appliance is intended for commercial use, and is only for professional use. It shall be used by trained,

qualified people.

NOTICE

EXHAUST FANS AND CANOPIES:

It is recommended that the range be installed under a ventilation hood.

Consult local codes for proper installation of hoods. Proper ventilation is the owner’s responsibility. Any problem

due to improper ventilation will not be covered by warranty.

S

TEP

1: U

NPACKING

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

All containers should be examined for damage before and during unloading. The freight carrier has assumed

responsibility for its safe transit and delivery. If damaged equipment is received, either apparent or concealed, a

claim must be made with the delivering carrier.

Apparent damage or loss must be noted on the freight bill at the time of delivery. The freight bill must then be

signed by the carrier representative (Driver). If the bill is not signed, the carrier may refuse the claim. The carrier

can supply the necessary forms.

A request for inspection must be made to the carrier within 15 days if there is concealed damage or loss that is not

apparent until after the equipment is uncrated. The carrier should arrange an inspection. Be certain to hold all

contents plus all packing material.

Do the following:

1. Cut the banding straps and remove the corrugated cardboard surrounding the range. If legs were shipped in

the same container, set them aside for installation in later steps of this procedure. Do not remove any tags or

labels attached to the range until the range is installed and working properly.

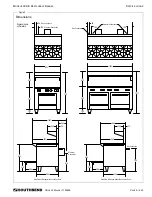

2. Lift the flue riser off the front of the skid (see Figure 3) and set it aside for installation later in this procedure.

3. Pull the shelf assembly out from under the base and set it aside for installation later in this procedure.

4. Unbolt the shipping hold-down brackets from the skid, then remove the brackets from the range.

5. If the range is to be installed on legs, go to Step 2a.

If the range is to be installed on casters, go to Step 2b.

O

WNER

’

S

M

ANUAL

1182499 P

AGE

13

OF

40

Summary of Contents for Southbend 436A-CE

Page 37: ...MODEL 400 CE RESTAURANT RANGES Notes PAGE 36 OF 40 OWNER S MANUAL 1182499...

Page 38: ...MODEL 400 CE RESTAURANT RANGES Notes OWNER S MANUAL 1182499 PAGE 37 OF 40...

Page 39: ...MODEL 400 CE RESTAURANT RANGES Notes PAGE 38 OF 40 OWNER S MANUAL 1182499...

Page 40: ...MODEL 400 CE RESTAURANT RANGES Notes OWNER S MANUAL 1182499 PAGE 39 OF 40...