Summary of Contents for DFLEX 1100

Page 2: ...DFLEX Assembly instructions 2...

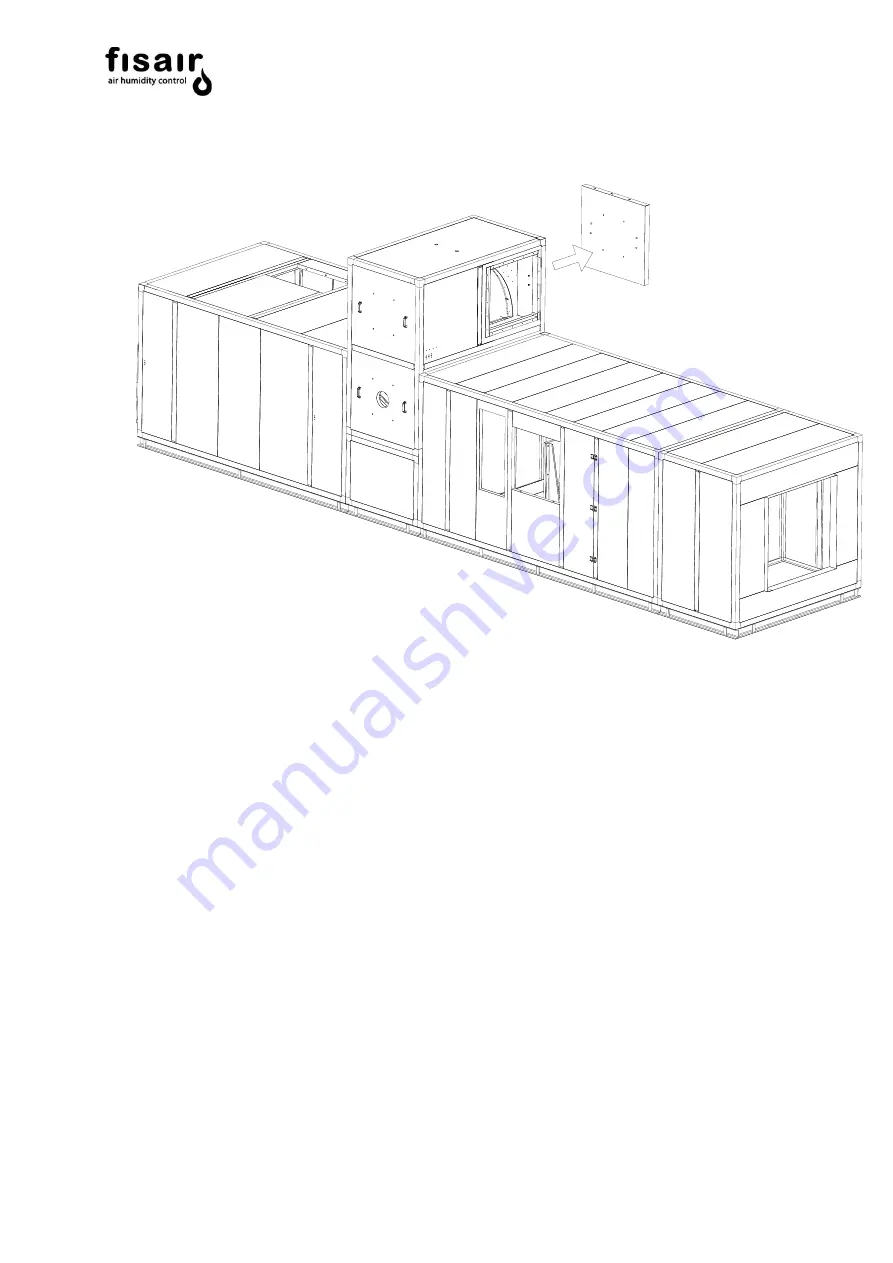

Page 16: ...DFLEX Assembly instructions 16 The following result is obtained...

Page 29: ...DFLEX Assembly instructions 29 DFLEX 1100 400V 5...

Page 30: ...DFLEX Assembly instructions 30 DFLEX 1100 440 480V NOT WIRING...

Page 31: ...DFLEX Assembly instructions 31 DFLEX 1300 400V 5...

Page 32: ...DFLEX Assembly instructions 32 DFLEX 1300 460V 5 NOT WIRING...

Page 33: ...DFLEX Assembly instructions 33 DFLEX 1700 400V 5...

Page 34: ...DFLEX Assembly instructions 34 DFLEX 2100 400V 5...

Page 35: ...DFLEX Assembly instructions 35 DFLEX 2100 460V 5 48 Elementos NOT WIRING...

Page 36: ...DFLEX Assembly instructions 36 DFLEX 2100 460V 5 45 elements Requires SSR in E4 NOT WIRING...