The Panda Generator

Seite/Page 52 Panda_4800i PMS_eng.R04 - Kapitel/Chapter 4: The Panda Generator

14.2.13

4.4

Operation manual

4.4.1 Preliminary remarks

Advices regarding Starter Battery

Fischer Panda recommends to use a normal starter battery. If the generator is required for extreme winter condi-

tions, the starter battery capacity should be doubled. It is recommended to regularly charge the starter battery by a

suitable battery-charging device (i.e. at least every two months). A correctly charged starter battery is necessary for

low temperatures.

4.4.2 Daily routine checks before starting

1. Oil level control (ideal level: 2/3 of maximum level).

Notice!:OIL PRESSURE CONTROL!

True, the diesel motor automatically switches off when

there is a lack of oil, but it is very damaging for the motor,

if the oil level drops to the lowest limit. Air can be sucked

in suddenly when the boat rocks in heavy seas, if the oil

level is at a minimum. This affects the grease in the bear-

ings. It is therefore necessary to check the oil level daily

before initially running the generator. The oil level must be

topped up to the 2/3 maximum level, if the level drops

below the mark between maximum and minimum levels.

You should change the oil independently from the ambient

temperature - see section 8.3, “Engine oil,” on page 126.

Engine oil volume see section 8.2, “Technical Data Engine,”

on page 125.

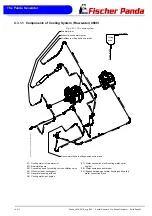

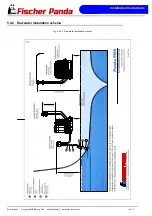

2. State of cooling water.

The external compensation tank should be filled up to a maximum during cold state. It is very important that large

expansion area remains above the cooling water level.

3. Open sea cock for cooling water intake.

For safety reasons, the sea cock must be closed after the generator has been switched off. It should be re-

opened before starting the generator.

4. Check raw water filter.

The raw water filter must be regularly checked and cleaned. The impeller fatigue increases, if residual affects the

raw water intake.

5. Check all hose connections and hose clamps are leakage.

Leaks at hose connections must be immediately repaired, especially the raw water impeller pump. It is certainly

possible that the raw water impeller pump will produce leaks, depending upon the situation. (This can be caused

by sand particles in the raw water ect.) In this case, immediately exchange the pump, because the dripping water

will be sprayed by the belt pulley into the sound insulated capsule and can quickly cause corrosion.

6. Check all electrical lead terminal contacts are firm.

This is especially the case with the temperature switch contacts, which automatically switch off the generator in

case of faults. There is only safe if these systems are regularly checked, and these systems will protect the gen-

erator, when there is a fault.

7. Check the motor and generator mounting screws are tight.

The mounting screws must be checked regularly to ensure the generator is safe. A visual check of these screws

must be made, when the oil level is checked.

Summary of Contents for Panda 4800i PMS

Page 36: ...Seite Page 36 Panda_5000i_PVMV N_Book_eng R02 14 2 13 Leere Seite Intentionally blank Basics ...

Page 130: ...Seite Page 130 Panda_4800i PMS_eng R04 14 2 13 Leere Seite Intentionally blank Tables ...

Page 148: ...Page 148 Chapter 2 General operation 14 2 13 Intentionally left blank General operation ...

Page 156: ...Page 156 Chapter 3 Installation 14 2 13 Intentionally left blank Installation ...

Page 158: ...Page 158 Chapter 4 Maintenance 14 2 13 Intentionally left blank Maintenance ...

Page 164: ...Page 164 Chapter 6 Annex 14 2 13 Intentionally left blank Annex ...