321144

110

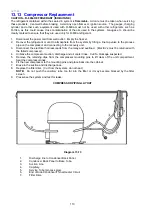

13.13 Compressor Replacement

CAUTION – R-600a REFRIGERANT (ISOBUTANE)

The refrigerant contained within the sealed in system is

flammable.

All care must be taken when servicing

these products. Vent well before brazing. Avoid any open flames or ignition source. The gauges, charging

cylinder and other such equipment used with R-600a must not be used with other refrigerants such as

R-134a, as this could cause cross contamination of the oils used in the systems. Gauges etc. should be

clearly marked to ensure that they are used only for R-600a refrigerant.

1. Disconnect the power cord from wall outlet. Empty the freezer.

2. Recover the refrigerant or vent to atmosphere from the system by fitting a line tap valve to the process

pipe on the compressor and connecting to the recovery unit.

3. Disconnect the electrical harness leads from the relay and overload. (Electric’s must be returned with

the failed compressor).

4. Unbraze the compressor suction, discharge and oil cooler lines. Cut if a blockage suspected.

5. Remove the retaining clips from the compressor mounting pins to lift clear of the unit compartment.

Seal the compressor lines.

6. Fit the new compressor to the mounting pins and place back into the cabinet.

7. Braze in the suction and discharge lines.

8. Replace the filter drier. (Cut from the system, do not heat.)

NOTE:

Do not push the capillary tube too far into the filter or it may become blocked by the filter

screen.

9. Pressurise the system and test for leaks.

COMPRESSOR PIPING LAYOUT

Diagram 13.13

1.

Discharge line to Condenser Back Panel.

2.

Condenser Back Panel to Base Tube.

3.

Suction Line.

4.

Capillary.

5.

Service Tube (process pipe).

6.

End of Side Condenser/Throat Heater Circuit.

7.

Filter Drier

.

Summary of Contents for 635 Active Smart

Page 1: ...321144 Service Manual 635 680 790 900 Active Smart Refrigerator Freezer R134a R600a Systems...

Page 2: ...321144 2...

Page 96: ...321144 96 Photo 12 22 5...

Page 100: ...321144 100 Diagram 12 25...

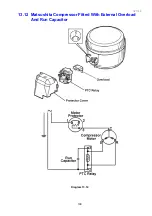

Page 108: ...321144 108 13 11 Embraco Compressor Fitted With External Overload Diagram 13 11...

Page 114: ...321144 114 14 2 Non Ice Water Models Wiring Diagram...

Page 116: ...321144 116 14 4 Ice Water Models Wiring Diagram...

Page 117: ...321144 117 14 5 900 Models Power Control Module Wiring Connections Reciprocating Compressor...

Page 118: ...321144 118 14 6 900 Models Wiring Diagram Reciprocating Compressor...

Page 119: ...321144 119 14 7 900 Models Power Control Module Wiring Connections VC Compressor...

Page 120: ...321144 120 14 8 900 Models Wiring Diagram VC Compressor...

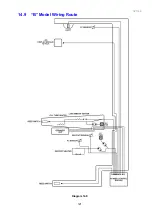

Page 121: ...321144 121 14 9 B Model Wiring Route Diagram 14 9...

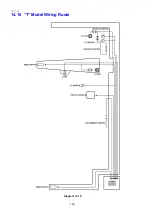

Page 122: ...321144 122 14 10 T Model Wiring Route Diagram 14 10...

Page 145: ......