321144

102

13.5 Brazing Off The System

Brazing off a system that uses flammable refrigerant is no more dangerous than a brazing of a refrigeration

system that contains R12 that, when burnt, produces phosgene gas.

R600a will burn if it leaks from the system and is ignited.

Crimp-off pliers should be adjusted to prevent any leak. It is recommended that two pair of pliers are used

for the process.

Points to remember are:

•

Always work in a well-ventilated area.

•

Have your crimp-off pliers adjusted correctly.

•

Crimp the filter dryer process pipe off first.

•

Open the high side valve on the service manifold and allow liquid trapped in the high side hose to enter

the system, as this is part of the total refrigerant charge.

•

Disconnect the hose/fitting. Close the end of the tube and braze off.

•

Repeat the process on the compressor process pipe.

Should the system be undercharged after the service manifold is disconnected, the problem could have

arisen from the fitting of a line tap valve to the process pipe, in that it is very easy to introduce non-

condensables into the system at this point due to the negative pressure in the compressor shell. The

practice of charging through line tap valves is not recommended.

As the amount of gas needed is so small to make the correction, it is best to evacuate and recharge the

system again with the correct charge.

13.6 Pressure Testing Of The Refrigeration System

CAUTION – R-600a REFRIGERANT (ISOBUTANE)

The refrigerant contained within the sealed in system is

flammable.

All care must be taken when servicing

these products. Vent well before brazing. Avoid any open flames or ignition source. The gauges, charging

cylinder and other such equipment used with R-600a must not be used with other refrigerants such as

R-134a, as this could cause cross contamination of the oils used in the systems. Gauges etc. should be

clearly marked to ensure that they are used only for R-600a refrigerant.

The use of the in-line pressure gauge can speed up and eliminate the incorrect diagnosis of a leak within a

refrigeration system. In some cases it has been found to be the services manifold that was being used that

was leaking and not the system. There are very few parts on the in-line pressure gauge that can leak.

Rule one:

In pressure testing any cabinet, before disconnecting any joint please be 100% sure that it is not the joint

that is at fault, otherwise a lot of time can be lost looking for a joint/leak that doesn't exist.

Rule two:

Only use dry nitrogen to pressure test a system.

NOT REFRIGERANT OR COMPRESSED AIR.

NEVER OXYGEN

Rule three:

Don’t over pressurise the system. It could be dangerous.

How to use the In-line Pressure Gauge:

Step 1:

Reclaim the refrigerant from the system (refer to Section 13.4) and purge the system with Dry Nitrogen.

Step 2:

Cut and connect the pipe circuit to be tested to the in-line pressure gauge and braze this joint.

Step 3:

At the other end of the pipe circuit being tested, crimp off the pipe with crimp off pliers and braze this end off

to totally seal the circuit.

Summary of Contents for 635 Active Smart

Page 1: ...321144 Service Manual 635 680 790 900 Active Smart Refrigerator Freezer R134a R600a Systems...

Page 2: ...321144 2...

Page 96: ...321144 96 Photo 12 22 5...

Page 100: ...321144 100 Diagram 12 25...

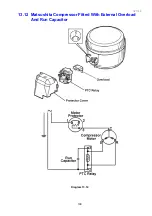

Page 108: ...321144 108 13 11 Embraco Compressor Fitted With External Overload Diagram 13 11...

Page 114: ...321144 114 14 2 Non Ice Water Models Wiring Diagram...

Page 116: ...321144 116 14 4 Ice Water Models Wiring Diagram...

Page 117: ...321144 117 14 5 900 Models Power Control Module Wiring Connections Reciprocating Compressor...

Page 118: ...321144 118 14 6 900 Models Wiring Diagram Reciprocating Compressor...

Page 119: ...321144 119 14 7 900 Models Power Control Module Wiring Connections VC Compressor...

Page 120: ...321144 120 14 8 900 Models Wiring Diagram VC Compressor...

Page 121: ...321144 121 14 9 B Model Wiring Route Diagram 14 9...

Page 122: ...321144 122 14 10 T Model Wiring Route Diagram 14 10...

Page 145: ......