321144

106

13.9.1 Polyurethane Foam

The insulation material being used in refrigerator and home freezer cabinets is polyurethane foam.

Polyurethane foam is a two-part mix, consisting of a pre-mix and an isocyanide. The pre-mix contains:

polyol, catalyst, silicone surfactant, water and fluorocarbon-II. The isocyanate is 4,41 diphenyl methane di-

isocyanate, or M.D.I. for short. In the past, tollene di-isocyanate, or T.D.I. for short, was used. When the

cabinet is "foamed" in the factory, the pre-mix and isocyanate are conditioned at a prescribed temperature in

advance. When the two ingredients are mixed together, they start to expand. Heat is produced by the

chemical reaction, which causes the fluorocarbon-II to boil, giving off a gas and creating a froth. It is this

froth that produces the cell structure. The size of the cells formed is controlled, to a large degree, by the

silicone surfactant, and this is critical in order to provide the required insulation properties.

Precautions necessary when using these Chemicals

:

Vapours from the pre-mix and isocyanate can be hazardous to your health, as can be skin contact from both

liquids. When using foam, make sure that adequate protective clothing is worn and sufficient ventilation is

present to remove the vapours that will be given off by the mixture. Should any of the chemicals come in

contact with your skin, rinse off with water. If a gas torch is used whilst repairing a refrigerator or freezer,

care must be taken not to set the foam alight, as cyanide fumes will be given off, as well as phosgene

generated from the burnt fluorocarbon present. Both of these gases can be dangerous if they are allowed to

accumulate and, for this reason sufficient ventilation must be present when doing repair work that is liable to

cause the generation of gases.

13.9.2 Safe Practices

(a) Do not inhale any vapour from the liquids.

(b) Measure chemicals by weight only and NOT by volume. (Not essential for small quantities used for

filling voids after repair).

(c) Avoid contact with skin or clothing.

(d) Use only in accordance with the recommended safety procedures.

(e) Remove, wash and decontaminate clothing before re-use.

(f) Do not smoke near foam operations.

(g) Isocyanate contact with the eyes:

Splashes of isocyanate in the eye are an irritant and may cause severe chemical conjunctivitis. If

any

chemical used in the foaming process enters the eyes, they should be washed out as soon as possible

with copious amounts of clean water for at least 15 minutes. It has been found that this will require the

help of another person to hold the victim's eye open. Foam that is frothing is particularly dangerous if it

enters the eyes.

Contact lenses must

NOT

be worn when working with isocyanates, for the chemicals can get in behind

these lenses and irreparable damage may occur to the eye while the lens is being removed prior to

flushing with water.

DO'S AND DON'TS WHEN USING THESE CHEMICALS

DO

wear sufficient protection - overalls, gloves and goggles - as directed by supervision or written

instructions.

DO

check that first aid facilities are always at hand.

DO

avoid personal contact with the chemical.

DO

wash thoroughly immediately on leaving the work area.

DO

seek medical attention at the first sign of breathing or chest troubles.

DO

take care when using a gas torch in the repair of a refrigerator and protect the foam from the heat.

DO

provide sufficient ventilation so as to avoid breathing any vapours whenever foam materials are

handled, mixed or poured.

THIS IS ESSENTIAL

. Cyanide fumes will be given off, together with

phosgene from the fluorocarbon present in each foam cell.

DON'T

let familiarity with the chemical breed contempt.

DON'T

ignore splashes on the skin - wash them off immediately with soap and water.

DON'T

take food or drink into an area where isocyanates are used.

DON'T

neglect splashes in the eye (see note above).

Summary of Contents for 635 Active Smart

Page 1: ...321144 Service Manual 635 680 790 900 Active Smart Refrigerator Freezer R134a R600a Systems...

Page 2: ...321144 2...

Page 96: ...321144 96 Photo 12 22 5...

Page 100: ...321144 100 Diagram 12 25...

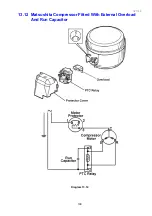

Page 108: ...321144 108 13 11 Embraco Compressor Fitted With External Overload Diagram 13 11...

Page 114: ...321144 114 14 2 Non Ice Water Models Wiring Diagram...

Page 116: ...321144 116 14 4 Ice Water Models Wiring Diagram...

Page 117: ...321144 117 14 5 900 Models Power Control Module Wiring Connections Reciprocating Compressor...

Page 118: ...321144 118 14 6 900 Models Wiring Diagram Reciprocating Compressor...

Page 119: ...321144 119 14 7 900 Models Power Control Module Wiring Connections VC Compressor...

Page 120: ...321144 120 14 8 900 Models Wiring Diagram VC Compressor...

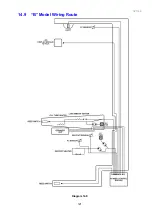

Page 121: ...321144 121 14 9 B Model Wiring Route Diagram 14 9...

Page 122: ...321144 122 14 10 T Model Wiring Route Diagram 14 10...

Page 145: ......