30

B

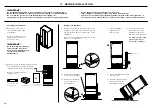

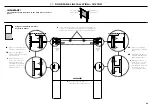

Remove hanging brackets

1

Remove the M8 washers and M8 nuts from the M8

studs at the top the door (

A

) using the hex key and

spanner. Keep the washers and nuts to reuse later.

2

Remove the hanging bracket from the top of each

door and set aside (

B

) for later installation.

A

D

C

C

D

E

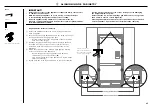

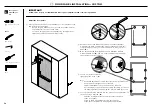

Attach the door and drawer handles (

C

)

3

Align the handle holes with the door

panel holes and secure the handle with

M5x25 pan head socket screws (4 for each

handle).

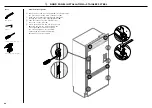

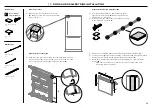

Attach side brackets and straps (

E

)

5

Align the brackets and straps to the holes

on the side of the panel and secure with

M5x14 mush cross-head SS screws (12).

Attach the hanging brackets (

D

)

4

Align the bracket to the holes and

secure with M5x14 mush cross-head

SS screws (12).

Internal box

B

Door panel

attachment kit

Side bracket

(10)

Side strap

(10)

#8 x 16

M

ush W

asher

Twin T

hr

ead

Philips S

cr

ew

#8 x 16

Mush Washer

Twin Thread

Philips Screw

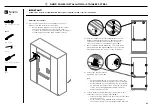

#8x16 mush washer screw

(24)

Door handle kit

M5 x 25

Pan Head

Socket S

cr

ew

M5 x 25

Pan Head

Socket S

cr

ew

M5x25 pan head socket

screw (8)

Tools

Hex key

FPA spanner

Cross-head screwdriver

Torx screwdriver

@0

DOOR PANEL INSTALLATION — CUSTOM